In the demanding fields of tunneling and ground engineering, projects often face significant delays and safety risks due to unconsolidated or cohesive soils, which require complex drilling and reinforcement methods. SupAnchor, a global leader in geotechnical solutions, has responded with the launch of its R Thread Self-Drilling Hollow Anchor, a key component of its advanced self drilling anchor system designed to streamline construction and ensure higher safety standards. This innovation addresses critical industry needs by integrating drilling and grouting into a single operation, reducing labor intensity and project timelines across various applications.

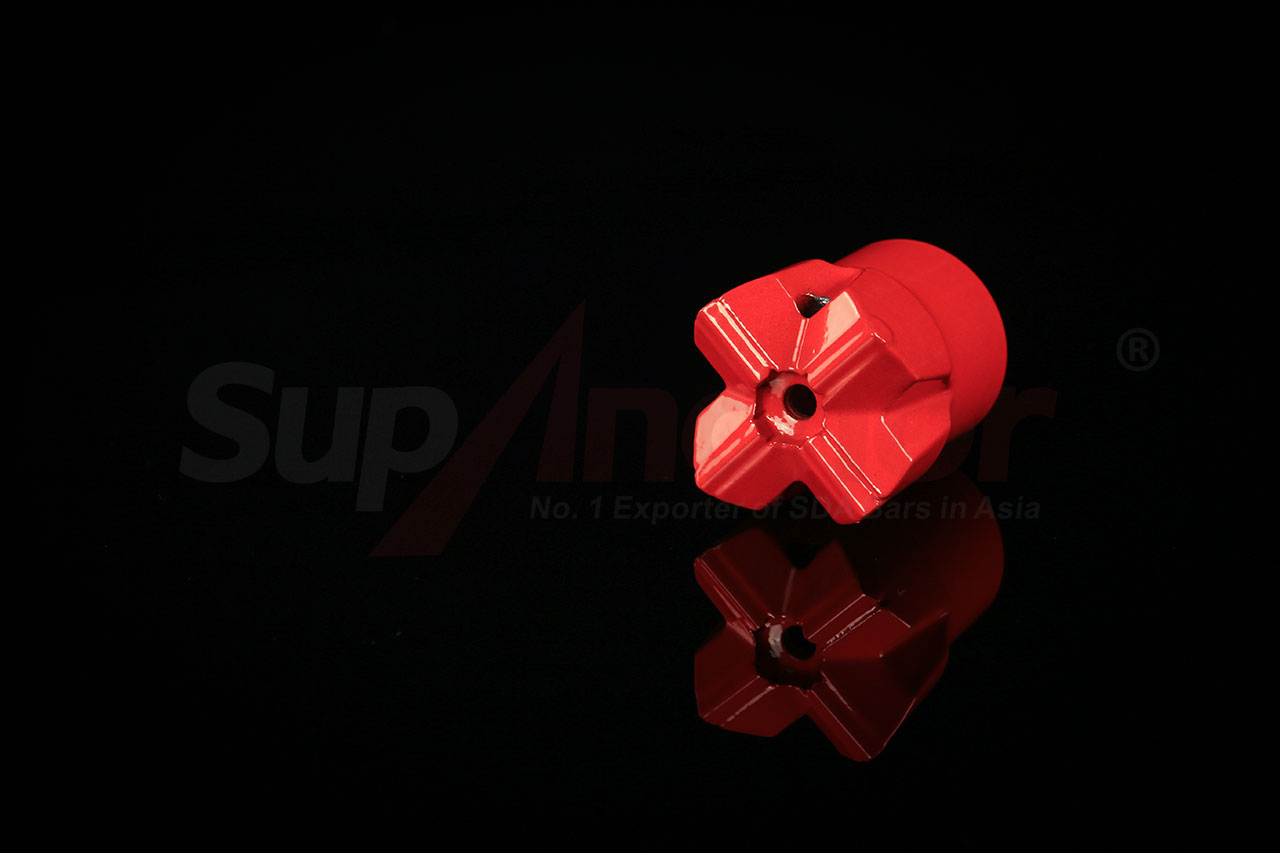

The SupAnchor R Thread Self-Drilling Hollow Anchor stands out through its innovative design, based on the "3-in-1 principle" where a ribbed hollow steel bar functions as a sacrificial drilling rod, injection tube, and reinforcing bar simultaneously. This self drilling anchor bolt system is manufactured to ISO 10208 and ISO 1720 standards, ensuring reliable performance and quick on-site installation. Key technical features include multiple anti-corrosion options—hot-dip galvanizing for general use, SupCoating (HDG + Epoxy) for moderate corrosion resistance, and stainless steel for highly corrosive environments—extending service life in diverse conditions.

To illustrate the product's capabilities, here are selected technical specifications from key models, highlighting how they meet engineering demands for load capacity and durability:

| Model | Outer Diameter (mm) | Internal Diameter (mm) | Ultimate Load (kN) | Anti-Corrosion Option |

|---|---|---|---|---|

| R25N/12 | 25 | 12 | ≥200 | Hot-dip galvanizing |

| R32S/17 | 32 | 17 | ≥360 | Stainless steel |

| R32/320 | 32 | 19 | ≥320 | SupCoating |

These specifications demonstrate the product's ability to handle high loads in tough environments, from tunnel supports to slope stabilization. The hollow bar anchor design allows for efficient grout injection, enhancing bonding with soil and rock for superior geotechnical reinforcement. By solving common drilling challenges, this drill-and-grout bolt system reduces construction costs and improves site safety, making it a preferred choice for engineers.

The R Thread Self-Drilling Hollow Anchor is versatile, with primary applications in tunneling engineering for face support and forepoling, ground engineering for slope and foundation reinforcement, and other geotechnical projects requiring rapid anchoring in soft ground. Its integration of drilling and grouting makes it ideal for emergency repairs and temporary supports, where time and reliability are critical. This adaptability stems from the product's design, which accommodates various soil types and environmental conditions, ensuring consistent performance across projects.

SupAnchor's commitment to innovation is evident in its R&D efforts, which have led to the successful deployment of over 39,000,000 meters of self drilling anchor bars worldwide. This track record underscores the reliability of the R thread product and its role in enhancing global infrastructure safety. The brand's focus on ISO-certified manufacturing processes ensures that each self drilling anchor bolt meets stringent quality standards, fostering trust among contractors and engineers.

In the context of rising global infrastructure demands, the SupAnchor self drilling anchor system offers significant value by improving construction efficiency and reducing risks in mining, transportation, and urban development projects. Its use contributes to safer tunneling operations and more stable ground engineering, aligning with industry trends towards sustainable and resilient construction. The product's market appeal is boosted by SupAnchor's reputation as a professional and collaborative partner, providing tailored solutions for complex geotechnical challenges.

Looking ahead, SupAnchor continues to innovate, with plans to expand its product range and support global projects through advanced geotechnical reinforcement systems. The brand's message of professionalism, innovation, and collaboration resonates in its approach to customer needs, ensuring long-term partnerships and project success.

An in-depth industry report on how SupAnchor's self drilling anchor bolts solved complex geological challenges in a tunneling project, with technical insights and global trends.

SupAnchor introduces a new self drilling anchor system with R thread technology, enhancing safety and speed in tunneling and ground engineering for challenging soil conditions.

Exploring how SupAnchor's self drilling anchor system provides robust geotechnical reinforcement for challenging construction sites, ensuring stability and safety in modern infrastructure.

SupAnchor unveils its GFRP Dowel Bar, a high-strength, non-corrosive solution for construction joints in pavements and structures, offering over 100 years of service life and superior load transfer efficiency.

A European urban tunneling project leverages SupAnchor's self-drilling anchor systems to address complex geological challenges, advancing geotechnical engineering standards and safety.