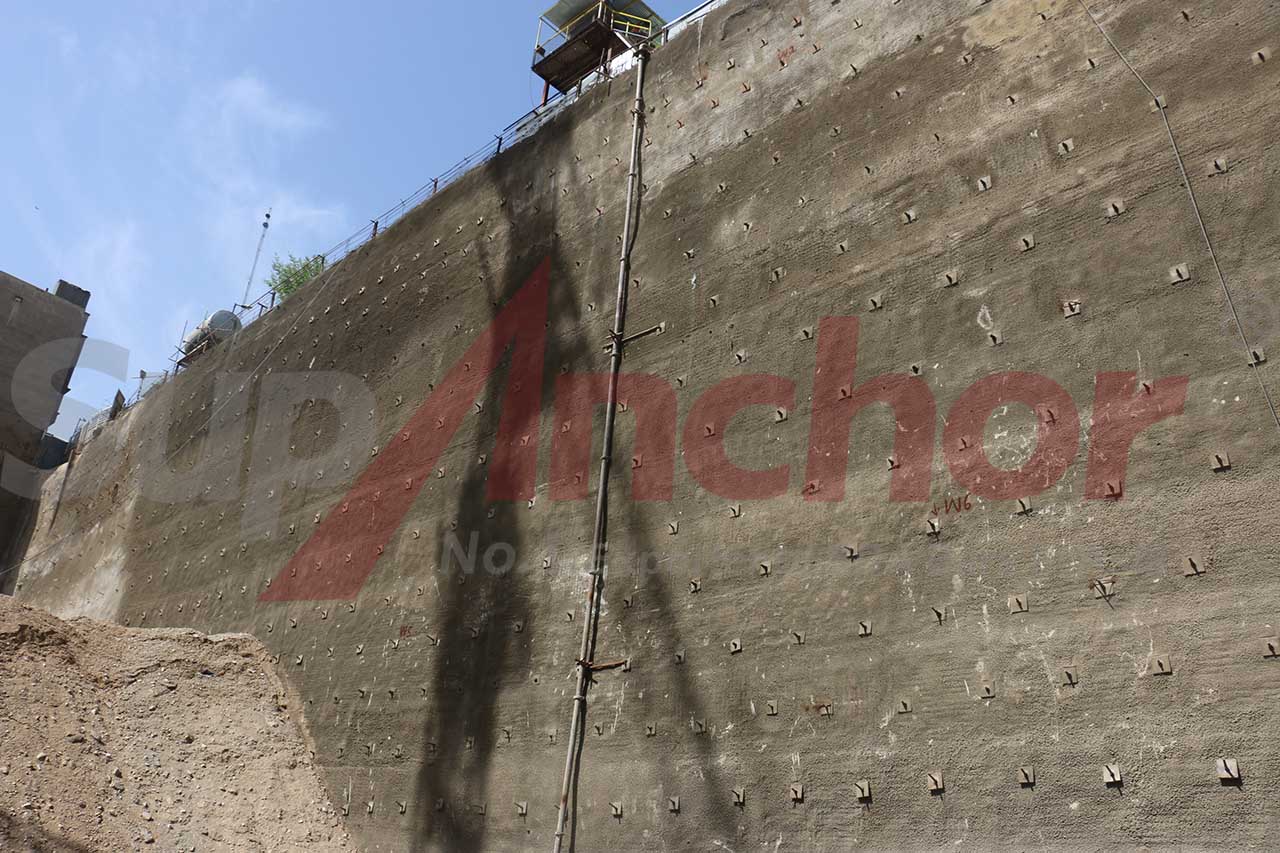

In the demanding landscapes of European and American construction projects, such as large-scale urban developments in seismic zones or coastal infrastructure with high corrosion risks, engineers face persistent challenges in formwork applications. SupAnchor, a leading innovator in geotechnical reinforcement systems, has stepped up to address these issues with the launch of its SupFRP® GFRP Tie Rod. This product introduction marks a significant advancement in formwork technology, designed to streamline processes and enhance durability without the need for removal post-construction.

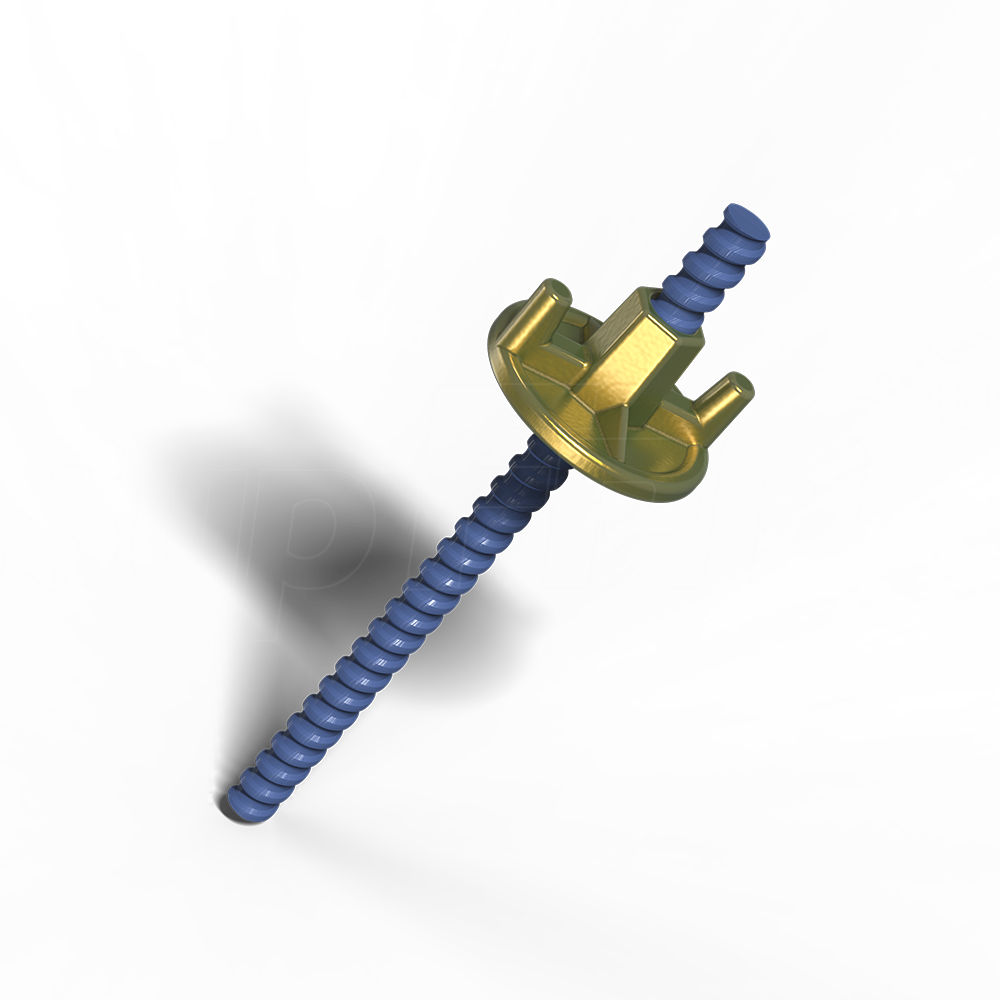

The SupFRP® GFRP Tie Rod is engineered to replace traditional steel tie rods in formwork, leveraging glass fiber reinforced polymer (GFRP) for superior performance. Its development stems from SupAnchor's commitment to solving real-world engineering problems, such as reducing transportation and storage costs in projects spanning tunnels, mining operations, and high-rise buildings. By eliminating the removal step, this product not only cuts operational expenses but also minimizes environmental impact, aligning with global sustainability goals in infrastructure development.

At the core of this innovation are the technical specifications that ensure reliability and efficiency. The SupFRP® GFRP Tie Rod is manufactured to match the thread profile of standard steel rods, allowing seamless integration with existing accessories. Key parameters from the product introduction, such as high corrosion resistance, guaranteed tensile load, and easy handling, directly address engineering challenges like material degradation in harsh environments and labor-intensive installations.

| Model | Outside Diameter (mm) | Guaranteed Tensile Load (kN) | Weight (kg/m) | Length Options (m) |

|---|---|---|---|---|

| T15/130 | 17 | 130 | 0.37 | 2 to 11 |

| T20/250 | 22 | 250 | 0.71 | 2 to 11 |

These specifications enable the tie rod to withstand high stress levels while offering versatility in length customization, making it ideal for diverse formwork scenarios. The non-conductive and non-magnetic properties further enhance safety in electrical or sensitive environments, reducing risks associated with traditional steel components. SupAnchor's focus on geotechnical reinforcement systems ensures that this product complements other solutions like the self drilling anchor bolt, providing a holistic approach to construction challenges.

The introduction of the SupFRP® GFRP Tie Rod holds significant value for the global construction industry. As infrastructure projects expand in complexity, from tunneling in mountainous regions to mining operations with corrosive soils, the need for durable and cost-effective solutions grows. This product supports geotechnical safety by offering a permanent application that reduces maintenance and improves long-term stability.

SupAnchor's role as a soil nail system manufacturer extends to this innovation, reinforcing its expertise in ground anchor bolt factory production. By integrating keywords like geotechnical reinforcement system and hollow bar anchor into real-world applications, the company demonstrates a commitment to advancing construction methodologies worldwide.

SupAnchor's reputation for professionalism and innovation is bolstered by this product launch. With ISO certifications and a track record of successful global projects, the company invests heavily in R&D to address evolving market needs. The SupFRP® GFRP Tie Rod exemplifies this approach, showcasing how collaborative efforts with engineers and contractors lead to tailored solutions that enhance project outcomes.

The brand message of being professional, innovative, and collaborative resonates throughout this development. By offering products like the drill-and-grout bolt alongside the GFRP tie rod, SupAnchor positions itself as a key player in the geotechnical sector, driving progress through continuous improvement and customer-centric design.

In conclusion, the SupFRP® GFRP Tie Rod represents a forward-thinking solution for modern formwork challenges. Its technical superiority, coupled with SupAnchor's industry leadership, promises to elevate standards in construction safety and efficiency. For more insights, users are encouraged to explore related resources, including demonstration videos, to see this innovation in action across various applications.

SupAnchor's innovative self drilling anchor system addresses complex geological challenges in infrastructure projects, ensuring stability and reducing construction risks with advanced geotechnical reinforcement.

SupAnchor's new GFRP tie rod offers a permanent, corrosion-resistant alternative to steel, enhancing safety and reducing costs in global construction projects.

An in-depth look at how SupAnchor's self-drilling anchor bolts provided critical ground stabilization in a challenging geotechnical project, showcasing technical innovation and industry-wide implications for safety and efficiency.

SupAnchor launches a corrosion-resistant GFRP solid bolt for geotechnical projects, enhancing safety in mining, tunneling, and infrastructure with lightweight design and high tensile strength.

An industry report on SupAnchor's self drilling anchor bolts used in a challenging Alpine railway tunnel, highlighting technical specs, project impact, and global geotechnical trends.