In infrastructure projects across Europe and America, engineers frequently encounter challenges such as corrosion in harsh environments and the need for lightweight materials to ease construction. SupAnchor® has addressed these issues with the introduction of its GFRP Mesh, a high-performance grid product designed to replace traditional welded metal meshes. This innovation is particularly vital in projects involving concrete structures, where durability and safety are paramount. For instance, in highway overlays or building repairs, SupAnchor's GFRP Mesh ensures reliable performance while reducing maintenance costs and improving structural integrity.

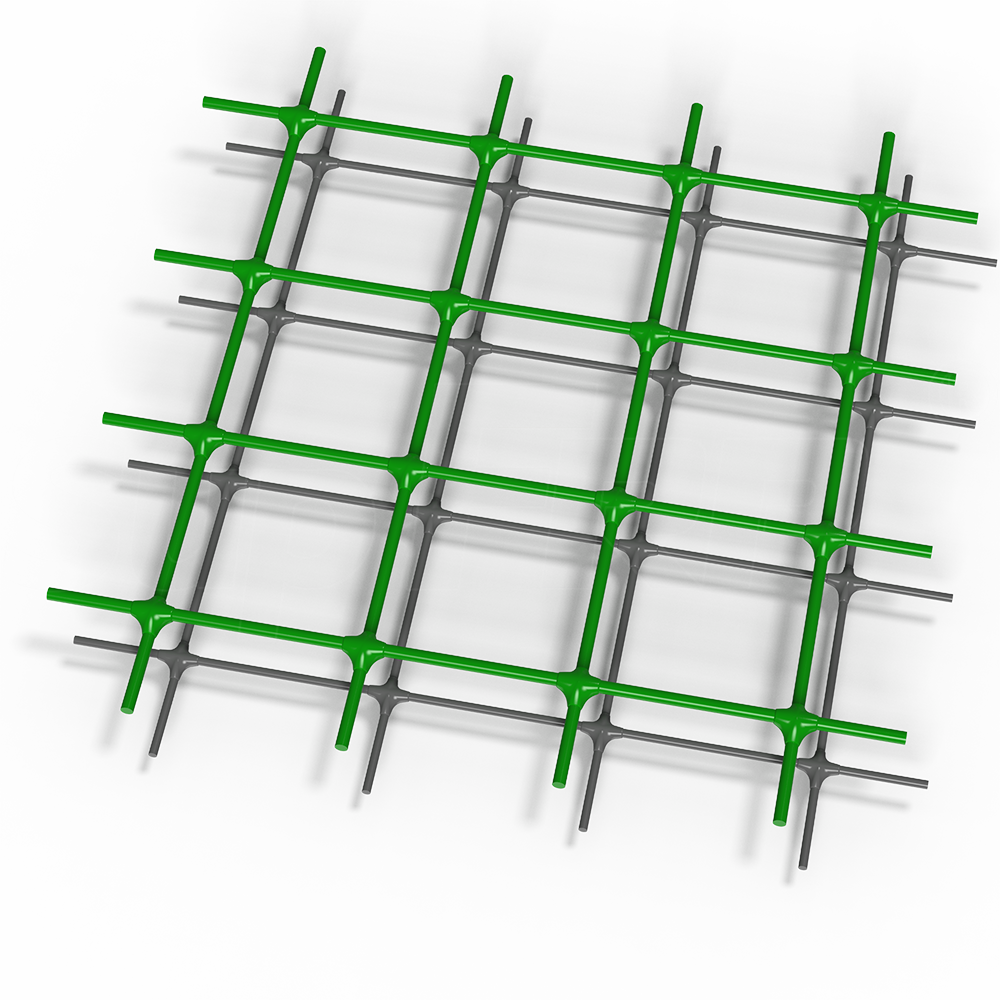

The SupAnchor® GFRP Mesh is assembled from longitudinal and transverse GFRP rods, with joints fixed by impregnated polymer yarn for strength. Key technical features include high corrosion resistance, high strength, non-conductivity, non-magnetic properties, and lightweight design, making it an excellent alternative to metal meshes. On construction sites, these attributes translate to easier handling and installation, reducing labor time and enhancing safety. For example, in flat slab construction, the mesh's flexibility allows for seamless integration, while its non-conductive nature prevents electrical hazards in sensitive environments.

To meet diverse engineering needs, SupAnchor offers various configurations, as detailed in the table below. This adaptability ensures that the GFRP Mesh can be customized for specific applications, from small repairs to large-scale projects.

| Model | Rod Diameter (mm) | Jointing Load (kN) | Grid Size (mm) |

|---|---|---|---|

| M4 | 4 | 2 | 100x100, 150x150, other sizes available |

| M6 | 6 | 3 | 100x100, 150x150, other sizes available |

| M8 | 8 | 5 | 100x100, 150x150, other sizes available |

These specifications enable the mesh to withstand high loads and environmental stresses, solving common engineering challenges like rust in coastal areas or electrical interference in industrial settings. When integrated with other SupAnchor solutions, such as the self drilling anchor system, it forms a comprehensive geotechnical reinforcement system for complex projects.

The GFRP Mesh is versatile, with main applications including roof and wall protection, repair of concrete structures, flat slab construction, and highway overlays. In global infrastructure, this contributes to safer and more sustainable developments. For example, in tunneling and mining, where corrosion and weight are critical factors, the mesh offers a durable alternative that enhances geotechnical safety. Its use in highway projects reduces long-term maintenance, aligning with trends toward resilient transportation networks.

SupAnchor's product range, including the GFRP Mesh and complementary items like the self drilling anchor bolt, supports a holistic approach to construction challenges. This geotechnical reinforcement system ensures that structures can endure harsh conditions, from urban renovations to remote mining sites. By incorporating lightweight materials, projects become more efficient, reducing carbon footprints and improving worker safety.

SupAnchor has built a reputation for professionalism and innovation through extensive research and development. The company holds ISO certifications and has been involved in numerous global projects, from European skyscrapers to American highways. Their collaborative approach with engineers and contractors ensures that products like the GFRP Mesh are tailored to real-world needs, emphasizing reliability and performance.

The brand message of being professional, innovative, and collaborative is evident in their product offerings. Beyond the GFRP Mesh, SupAnchor provides solutions like hollow bar anchors and drill-and-grout bolts, reinforcing their position as a leading soil nail system manufacturer. This commitment drives continuous improvement, making SupAnchor a trusted partner in the construction industry worldwide.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.