In the face of escalating urban development and infrastructure demands, construction projects worldwide are grappling with intricate geotechnical hurdles. A recent case study from a high-speed rail tunnel project in the Alps exemplifies this, where unstable granite formations and seismic risks necessitated a robust ground stabilization anchor system. SupAnchor's self drilling anchor system was deployed to ensure foundational integrity, showcasing its pivotal role in tunneling and slope stabilization applications.

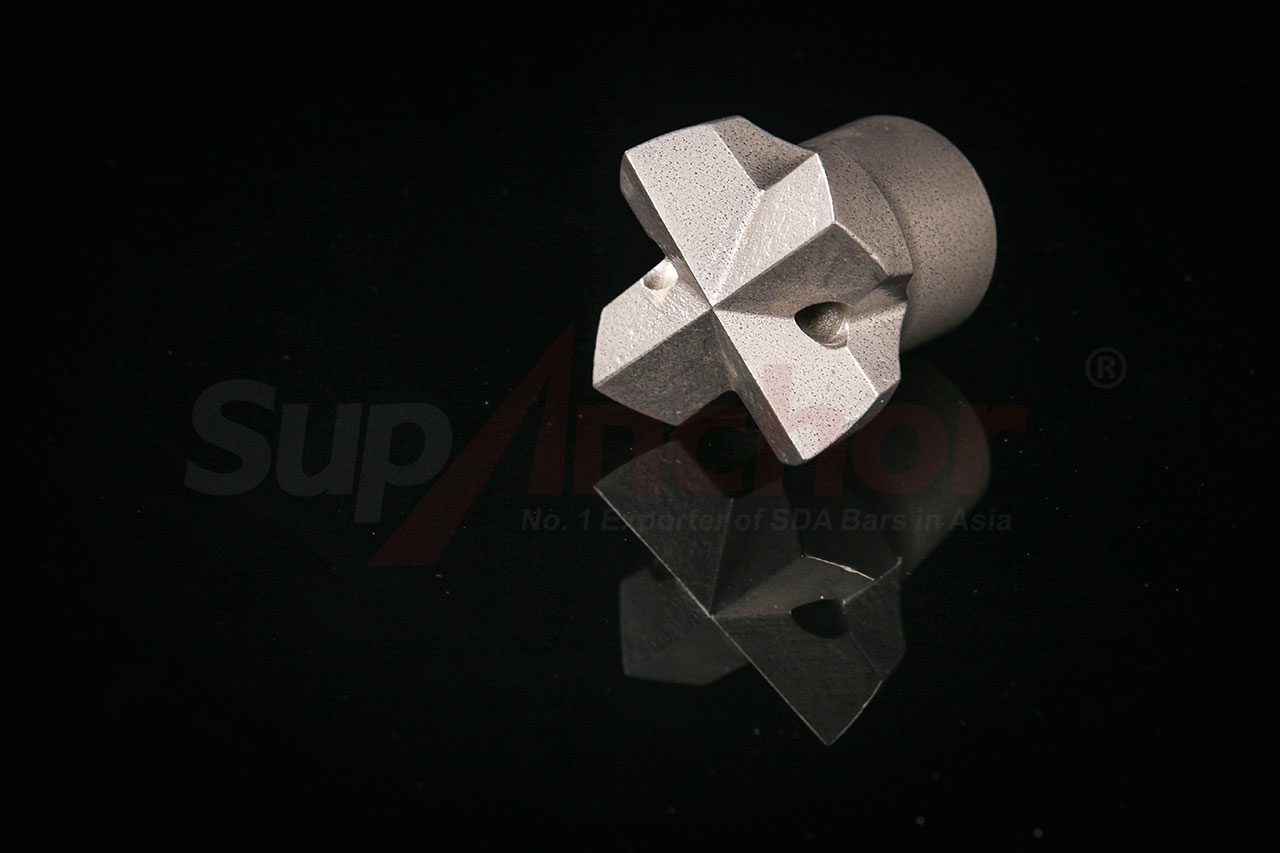

The construction site image vividly illustrates engineers installing SupAnchor's hollow bar anchors in real-time, utilizing a drill-and-grout bolt approach that streamlines operations. This geotechnical reinforcement system is engineered to penetrate challenging substrates while providing immediate load-bearing support. Key product parameters, derived from SupAnchor's specifications, include:

| Parameter | Value | Application Benefit |

|---|---|---|

| Diameter | 32-50 mm | Suitable for varied soil and rock densities in civil engineering |

| Length | Up to 15 meters | Enables deep anchoring for slope stabilization and retaining walls |

| Tensile Strength | 550 MPa | High resistance to stress, ideal for underground mining and tunneling |

| Corrosion Protection | Hot-dip galvanized or epoxy-coated | Ensures longevity in harsh environmental conditions |

| Installation Speed | Single-pass operation | Reduces labor costs and project timelines significantly |

These specifications empower the self drilling anchor bolt to address site-specific challenges, such as soil liquefaction in earthquake-prone areas or erosion control in coastal projects. By integrating with a comprehensive anchor bolt system for geotechnical engineering, SupAnchor's solutions offer a seamless blend of efficiency and reliability.

The global construction sector is undergoing a transformation, driven by urbanization, climate resilience, and safety regulations. SupAnchor's ground anchor bolt factory plays a critical role in this landscape, supplying products that cater to diverse needs, from rock bolts for underground mining to micropile hollow bar anchors for foundation support in congested urban zones. For instance, the increasing adoption of self drilling anchor for retaining walls in highway projects underscores the trend towards sustainable and cost-effective geotechnical solutions.

Moreover, with infrastructure investments soaring in regions like North America and Europe, the demand for advanced geotechnical reinforcement systems is on the rise. SupAnchor's SDA bolt factory direct supply model ensures timely delivery and quality assurance, supporting projects that prioritize safety and innovation. This aligns with broader industry shifts towards digitalization and eco-friendly practices, where the self drilling bolt for civil engineering reduces environmental impact by minimizing excavation and material waste.

SupAnchor, recognized as a leading soil nail system manufacturer, embodies a commitment to professionalism, innovation, and collaboration. The company's ISO 9001 certifications and involvement in global projects, such as dam reinforcements and skyscraper foundations, highlight its dedication to quality and research. By focusing on ground stabilization anchor system development, SupAnchor leverages cutting-edge technology to solve real-world engineering problems, often collaborating with academic institutions and industry partners to push boundaries.

Key brand attributes include a customer-centric approach, where the self drilling anchor system is tailored to project-specific requirements, and a focus on continuous improvement through feedback loops. This has cemented SupAnchor's reputation as a trusted provider in the geotechnical sphere, with a portfolio spanning transportation, energy, and residential sectors.

In conclusion, SupAnchor's self drilling anchor bolts represent a significant leap forward in geotechnical engineering, offering scalable solutions that enhance project safety and efficiency. As infrastructure needs evolve, the company's emphasis on innovation and direct supply positions it at the forefront of the industry, contributing to a safer and more sustainable built environment worldwide.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.