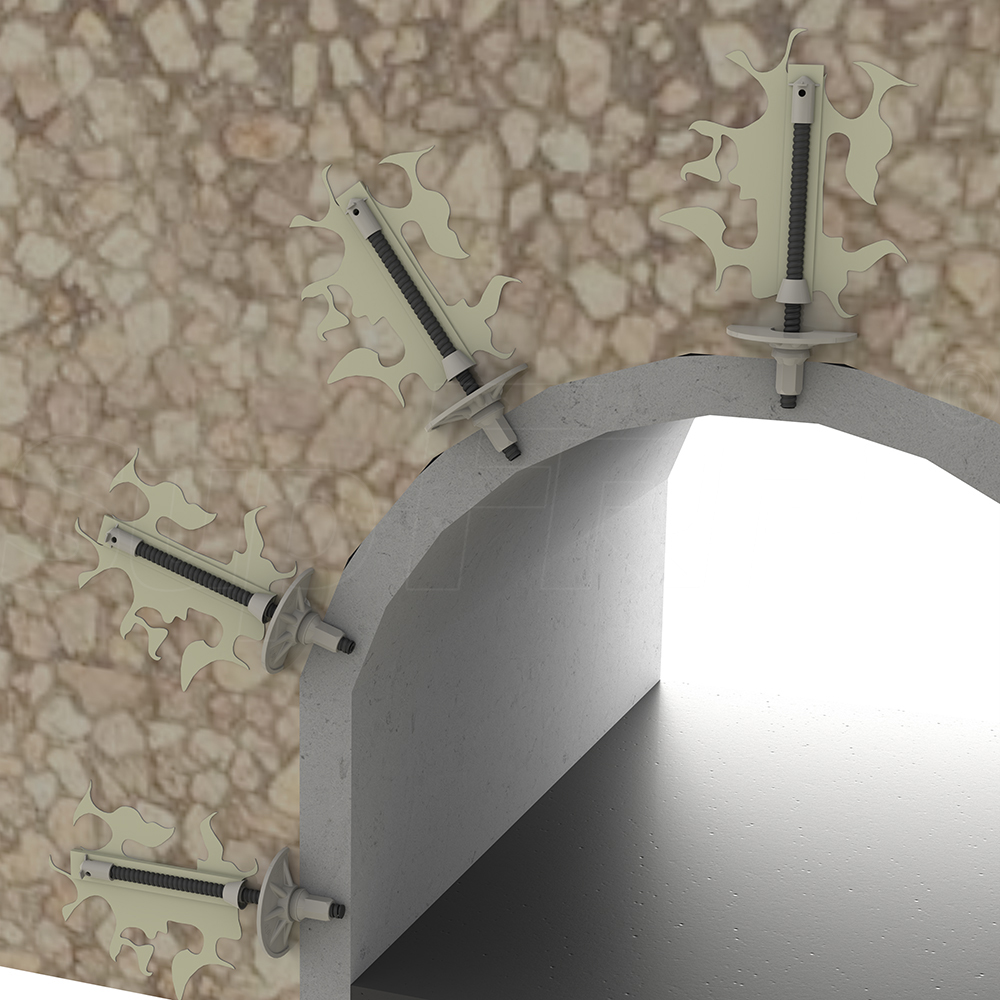

In the challenging landscapes of geotechnical engineering, from unstable slopes to deep tunneling projects, the need for reliable and durable support systems is critical. SupAnchor® addresses this with its innovative GFRP Hollow Injection Bolt, a core component of the SupFRP® series, designed to enhance project quality and safety. This self drilling anchor bolt integrates the functions of a rock bolt and injection, allowing for full grouting under high pressure to improve bonding and load-bearing capabilities. As infrastructure projects expand across Europe and America, the demand for advanced geotechnical reinforcement systems is on the rise, and SupAnchor is at the forefront with this cutting-edge solution.

The SupFRP® GFRP Hollow Injection Bolt is engineered to meet the rigorous demands of modern geotechnical projects. After injection, it remains in the borehole, working in tandem with plates and nuts to provide superior tensile strength and pressure resistance. Its lightweight design ensures easy handling, while the hollow structure facilitates efficient grouting, making it ideal for confined spaces and complex geological conditions. Key parameters include guaranteed tensile loads up to 490 kN, pressure resistance up to 30 MPa, and a weight as low as 0.58 kg/m, which collectively address common engineering challenges such as high-stress environments and corrosion risks.

To illustrate the technical prowess, here is a table summarizing selected models from the SupAnchor range:

| Model | Outside Diameter (mm) | Guaranteed Tensile Load (kN) | Pressure Resistance (MPa) | Weight (kg/m) |

|---|---|---|---|---|

| H25/220 | 25 | 220 | 5 | 0.64 |

| H28/320 | 28 | 320 | 5 | 0.88 |

| H32/360 | 32 | 360 | 5 | 1.20 |

| H22/230 | 22 | 230 | 18 | 0.58 |

These specifications enable the bolt to solve critical issues: the high tensile load ensures stability in dynamic environments, the corrosion resistance extends longevity in harsh conditions, and the low weight reduces installation time and labor costs. By incorporating features like cuttability and good bond force, this drill-and-grout bolt adapts seamlessly to various soil and rock types, enhancing overall project resilience.

The versatility of the GFRP Hollow Injection Bolt makes it indispensable across multiple sectors. Primary applications include:

Globally, the need for robust self drilling anchor systems is growing due to increasing infrastructure investments. In Europe, aging structures require reinforcement, while in America, new projects in seismic zones demand high-performance solutions. The SupAnchor bolt addresses these needs by offering a reliable, cost-effective alternative to traditional methods, thus contributing to enhanced safety and sustainability in geotechnical engineering.

SupAnchor® has established itself as a leader in geotechnical reinforcement through continuous innovation and research. The company's R&D efforts focus on developing products like the GFRP Hollow Injection Bolt, which adhere to international standards and ISO certifications, ensuring quality and reliability. By collaborating with engineers and contractors worldwide, SupAnchor delivers tailored solutions that meet diverse project requirements, reinforcing its reputation for professionalism and innovation.

The brand message of being professional, innovative, and collaborative is evident in their global projects, from large-scale tunneling in Europe to slope stabilization in North America. As a trusted ground anchor bolt factory, SupAnchor is committed to advancing geotechnical safety and efficiency, making it a preferred partner for complex engineering challenges.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.