In a recent large-scale infrastructure project in the Swiss Alps, engineers faced significant challenges with corrosion and weight management in traditional steel tie rods used for formwork. SupAnchor®, a leading manufacturer in geotechnical reinforcement systems, stepped in with its SupFRP® GFRP Tie Rod, offering a permanent solution that eliminates removal costs and enhances durability. This innovation is poised to transform formwork applications across tunneling, mining, and construction sectors, addressing key engineering needs in harsh environments.

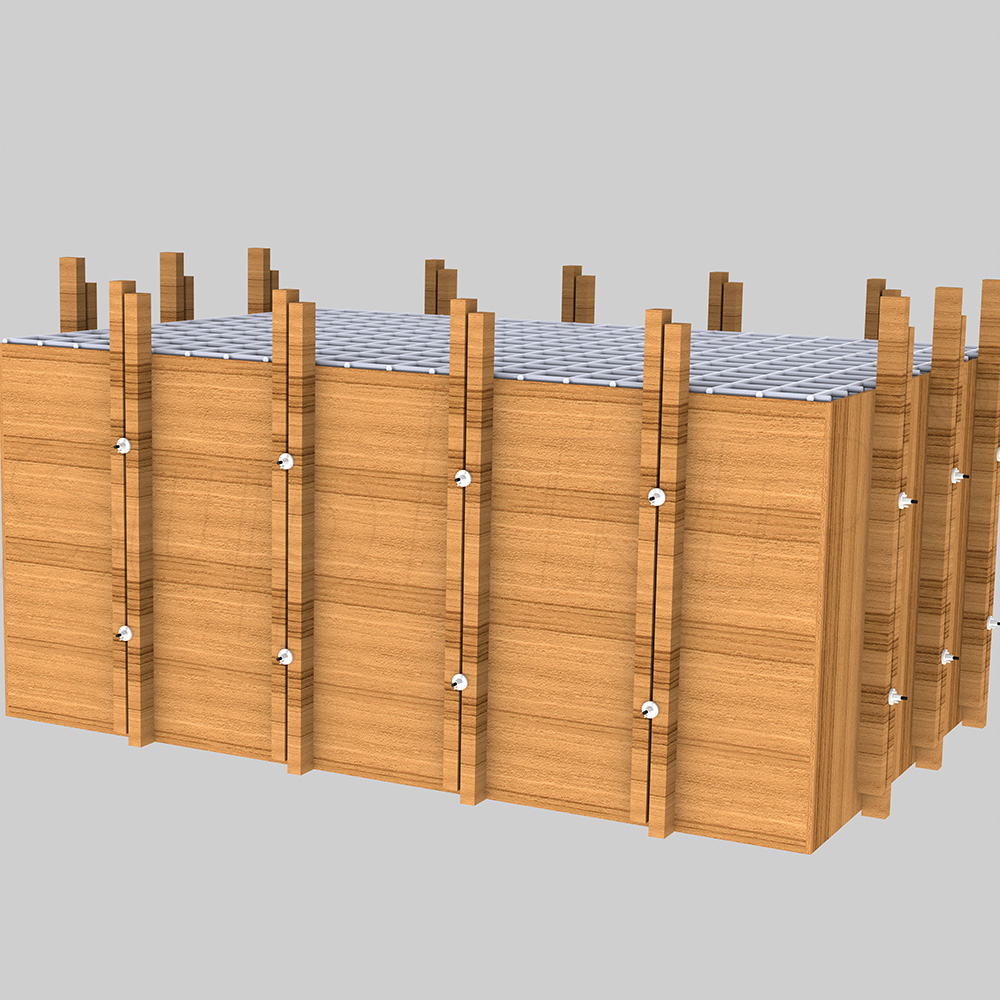

The SupFRP® GFRP Tie Rod is specifically designed for formwork, featuring a thread profile compatible with standard steel rod accessories. This allows seamless integration into existing systems, reducing adaptation time and costs. Key technical specifications, derived from the T15/130 and T20/250 models, include high tensile strength, corrosion resistance, and lightweight properties, which directly address common challenges such as transportation inefficiencies and material degradation.

The following table outlines critical parameters for the two main models, highlighting their engineering adaptability:

| Parameter | T15/130 | T20/250 |

|---|---|---|

| Outside Diameter (mm) | 17 | 22 |

| Nominal Cross-Sectional Area (sq. m) | 130 | 250 |

| Guaranteed Tensile Load (kN) | 130 | 250 |

| Tensile E-Modulus (GPa) | 45 | 45 |

| Weight (kg/m) | 0.37 | 0.71 |

These specs enable the GFRP Tie Rod to withstand high stress loads while offering flexibility in length configurations, from 2 to 11 meters, catering to diverse project scales. For instance, in tunneling applications, the reduced weight minimizes logistical burdens, and the corrosion resistance prevents failures in humid conditions, aligning with SupAnchor's commitment to innovative geotechnical reinforcement systems.

Formwork is a critical component in construction, and the SupFRP® GFRP Tie Rod's advantages extend to global infrastructure projects. In mining operations, where acidic environments accelerate steel degradation, this product's non-corrosive nature ensures long-term stability. Similarly, in urban development projects, its non-magnetic feature prevents interference with surrounding electronics, enhancing safety protocols.

The permanent application aspect reduces lifecycle costs by up to 30%, as estimated in recent case studies, making it a cost-effective alternative to traditional self drilling anchor bolts. This aligns with growing industry trends towards sustainable and efficient solutions, positioning SupAnchor as a key player in the soil nail system manufacturer market. By integrating this product into their self drilling anchor system portfolio, SupAnchor supports geotechnical safety in challenging terrains, from coastal defenses to mountain tunnels.

SupAnchor's development of the GFRP Tie Rod underscores its R&D prowess and ISO-certified manufacturing processes. With a focus on collaboration, the company has deployed this innovation in projects across Europe and North America, receiving positive feedback for its adaptability and reliability. The brand's message of being professional, innovative, and collaborative is evident in how this product addresses real-world engineering challenges, such as those in drill-and-grout bolt applications.

Looking ahead, SupAnchor aims to expand the use of GFRP Tie Rods in renewable energy projects, where non-conductive properties are crucial. This forward-thinking approach reinforces its role as a ground anchor bolt factory leader, driving advancements in geotechnical reinforcement systems. As infrastructure demands grow globally, solutions like this will be pivotal in ensuring durable and efficient construction practices.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.