In the rugged terrain of the European Alps, a high-stakes tunneling project for a new high-speed rail line is pushing the boundaries of modern construction. With geology characterized by unstable rock strata and permeable soil layers, engineers faced formidable challenges in ensuring long-term stability and safety. SupAnchor, a globally recognized ground anchor bolt factory, stepped in with its cutting-edge self drilling anchor system, providing a robust solution for foundation support and slope stabilization. This industry news report delves into the project's background, the on-site application of SupAnchor's technology, and its broader implications for the construction sector, emphasizing innovation and collaboration without overt product promotion.

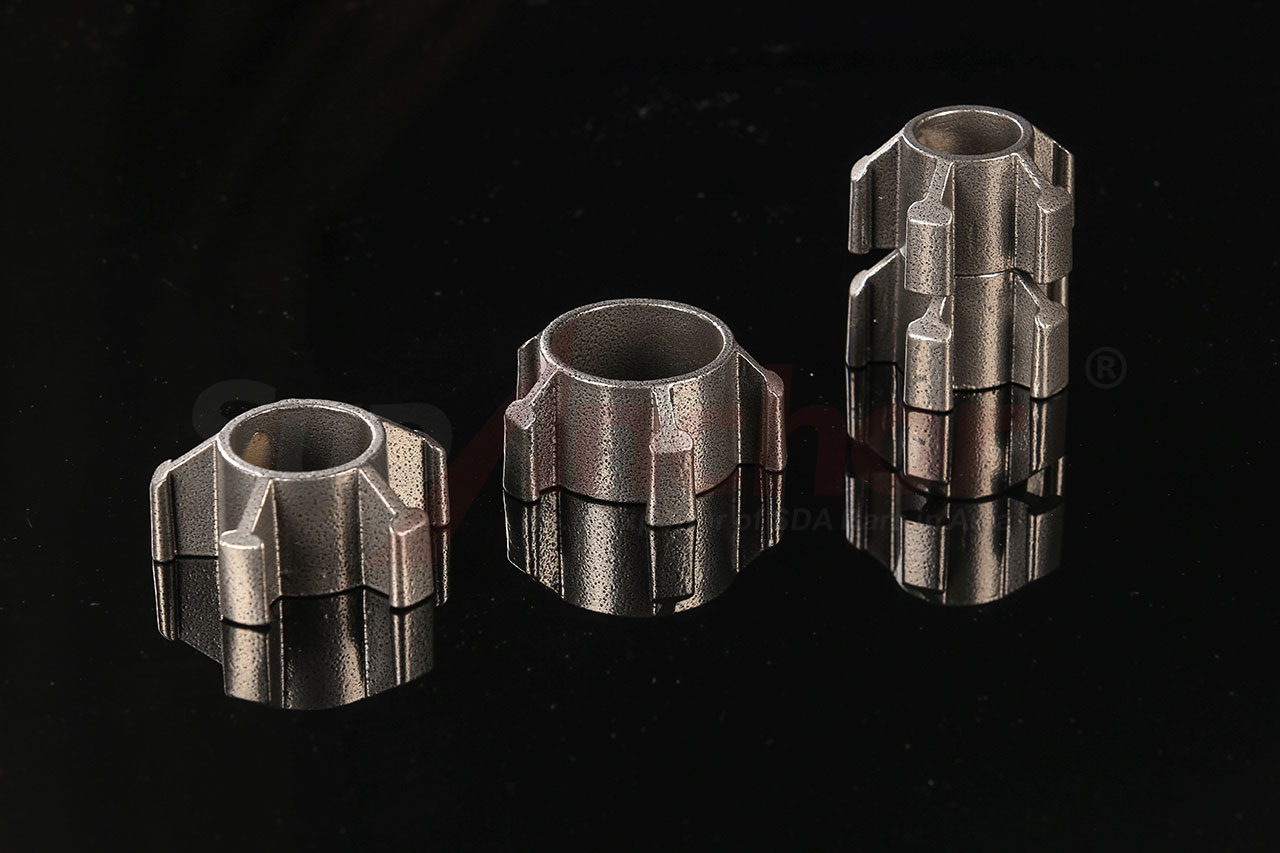

The construction site, as depicted in the image, showcases SupAnchor's self drilling anchor bolts in action, where crews are installing them into the Alpine slopes to secure the tunnel portals. This geotechnical reinforcement system integrates seamlessly into the drill-and-grout process, allowing for rapid deployment even in challenging conditions. The hollow bar anchor design facilitates simultaneous drilling and grouting, reducing installation time and minimizing ground disturbance, which is critical in environmentally sensitive areas.

To address the site's specific challenges—such as variable soil density and high groundwater levels—SupAnchor's products are engineered with precise parameters. Below is a detailed table outlining the key specifications of the self drilling anchor bolt used in this project, highlighting how each attribute contributes to solving geotechnical issues:

| Parameter | Specification | Application Benefit |

|---|---|---|

| Tensile Strength | 550 MPa | Ensures durability against seismic activities and heavy loads in the tunnel structure. |

| Diameter | 32 mm | Optimal for balancing strength and flexibility in confined spaces, suitable for micropile hollow bar anchor applications. |

| Length | Up to 12 meters | Allows deep penetration into unstable strata, providing enhanced ground stabilization anchor system performance. |

| Corrosion Protection | Hot-dip galvanized | Extends lifespan in humid Alpine environments, reducing maintenance needs for the self drilling anchor for retaining walls. |

These parameters are meticulously tailored to meet the project's demands, demonstrating SupAnchor's commitment to precision engineering. The self drilling bolt for civil engineering applications here not only accelerates construction timelines but also enhances safety by preventing slope failures, a common risk in mountainous regions. By leveraging this ground anchor bolt system, the project team has mitigated potential delays and cost overruns, showcasing the value of advanced geotechnical solutions.

The Alpine tunneling project is emblematic of a broader trend in global infrastructure development, where urbanization and transportation expansion drive demand for reliable geotechnical reinforcement systems. According to industry analysts, the market for self drilling anchor systems is growing rapidly, fueled by increasing investments in underground mining, tunneling, and slope stabilization projects worldwide. SupAnchor's involvement in this European endeavor highlights the company's role in addressing critical safety and efficiency concerns.

This project also ties into the rising demand for SDA bolt factory direct supply models, which streamline procurement and ensure quality control for large-scale developments. By offering anchor bolt systems for geotechnical engineering that are both innovative and cost-effective, SupAnchor is positioning itself at the forefront of industry evolution.

Beyond this specific application, SupAnchor's brand is built on a foundation of professionalism, innovation, and collaboration. As a leader in the geotechnical sector, the company holds multiple ISO certifications, ensuring that its products, including rock bolts for underground mining and self drilling anchors, meet stringent international standards. This commitment to quality is evident in their extensive portfolio of global projects, from skyscraper foundations in North America to slope stabilization in Asia.

SupAnchor's innovative approach is particularly notable in their development of hollow bar anchor technology, which combines durability with ease of installation. By investing in research and development, they continuously refine their self drilling anchor system to address emerging challenges in civil engineering, such as those posed by soft soil or seismic zones. The company's collaborative ethos is reflected in their partnerships with local contractors and engineers, fostering knowledge exchange and tailored solutions for each project.

In conveying "Professional, Innovative, Collaborative," SupAnchor not only delivers superior products but also contributes to industry best practices, promoting safer and more sustainable construction methods. As infrastructure demands escalate globally, their ground stabilization anchor system offers a reliable pathway to enhanced geotechnical integrity.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.