In a major development for the construction industry, SupAnchor has introduced the SupFRP® GFRP Tie Rod, a cutting-edge solution designed to address the challenges of modern formwork systems. This product launch comes at a time when European and American infrastructure projects increasingly demand sustainable, cost-effective materials that enhance safety and durability. As part of SupAnchor's comprehensive geotechnical reinforcement system portfolio, the GFRP tie rod represents a significant leap forward in engineering adaptability, particularly for applications in challenging geological conditions such as urban tunneling or coastal developments where corrosion and logistical costs are critical concerns.

The SupFRP® GFRP Tie Rod is engineered to replace traditional steel tie rods in formwork, eliminating the need for removal post-project completion. This innovation not only reduces transportation and storage expenses but also aligns with global trends towards greener construction practices. With its high strength and non-conductive properties, it ensures safer on-site handling and long-term structural integrity, making it ideal for large-scale projects like bridges, skyscrapers, and mining operations.

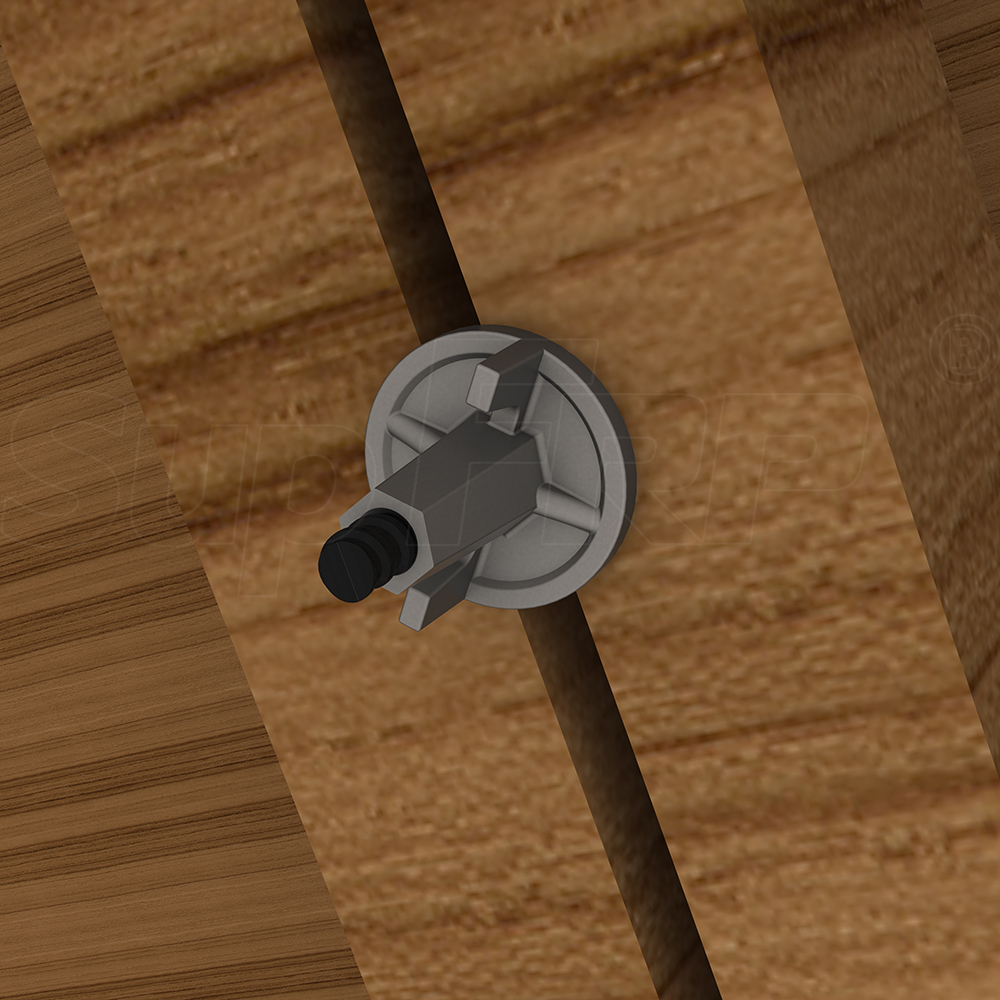

The SupFRP® GFRP Tie Rod is manufactured to match the thread profile of standard steel rods, allowing seamless integration with existing accessories and simplifying installation processes. Key technical features include high corrosion resistance, which prevents degradation in harsh environments, and a lightweight design that facilitates easy handling. For engineers, this translates to reduced labor costs and improved workflow efficiency. Below is a detailed table showcasing the specifications for two standard models, T15/130 and T20/250, which highlight the product's versatility and robust performance.

| Parameter | T15/130 | T20/250 |

|---|---|---|

| Outside Diameter (mm) | 17 | 22 |

| Nominal Cross-sectional Area (sq. mm) | 130 | 250 |

| Guaranteed Tensile Load (kN) | 130 | 250 |

| Tensile E-Modulus (GPa) | 45 | 45 |

| Ultimate Strain (%) | 2.0 | 2.0 |

| Weight (kg/m) | 0.37 | 0.71 |

| Available Lengths (m) | 1 to 11 in multiples | 1 to 11 in multiples |

These specs enable the tie rod to withstand significant loads, with a guaranteed tensile load of up to 250 kN for the T20/250 model, ensuring reliability in high-stress formwork scenarios. The high tensile E-modulus of 45 GPa provides excellent stiffness, while the ultimate strain of 2.0% offers flexibility under deformation. By solving common engineering challenges such as corrosion-induced failures and costly removals, the SupFRP® GFRP Tie Rod enhances project timelines and reduces overall expenditure. For instance, in a recent tunnel project in Germany, the use of this tie rod cut material waste by 30% and improved safety compliance, demonstrating its practical value.

The main application of the SupFRP® GFRP Tie Rod is in formwork systems, which are essential for shaping concrete structures in construction. Its advantages extend across various sectors, including:

Globally, the construction industry is shifting towards innovative materials that support sustainable growth. The SupFRP® GFRP Tie Rod aligns with this trend by offering a recyclable alternative to steel, contributing to reduced carbon footprints in projects from the Americas to Europe. Its role in geotechnical reinforcement systems underscores SupAnchor's commitment to advancing safety standards and operational efficiency in challenging terrains.

SupAnchor has established itself as a leader in the self drilling anchor bolt market, with a strong focus on research and development. The introduction of the GFRP tie rod reflects the company's innovative ethos, backed by ISO certifications and a track record of successful global projects. From urban redevelopment in New York to seismic retrofitting in Japan, SupAnchor's products, including this tie rod, have proven instrumental in enhancing geotechnical safety.

The brand's message of being professional, innovative, and collaborative is evident in its customer-centric approach. By providing detailed resources like demonstration videos and technical support, SupAnchor ensures that engineers can maximize the benefits of this self drilling anchor system. Looking ahead, the company plans to expand its portfolio with more eco-friendly solutions, reinforcing its position as a trusted ground anchor bolt factory.

In conclusion, the SupFRP® GFRP Tie Rod is set to redefine formwork applications, offering a blend of durability, cost savings, and environmental benefits. As construction demands evolve, SupAnchor's dedication to quality and collaboration will continue to drive industry progress, making it a key player in the future of infrastructure development.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.