In the demanding environments of tunneling and ground engineering, professionals grapple with unstable soils, tight deadlines, and safety concerns. SupAnchor, a leader in geotechnical solutions, has introduced the R Thread Self-Drilling Hollow Anchor system, designed to overcome these hurdles. This product addresses the inefficiencies of traditional casing methods in unconsolidated or cohesive soil, where drilling can be time-consuming and risky. With over 39,000,000 meters of self-drilling anchor bars deployed globally, SupAnchor demonstrates reliability and innovation in enhancing project outcomes.

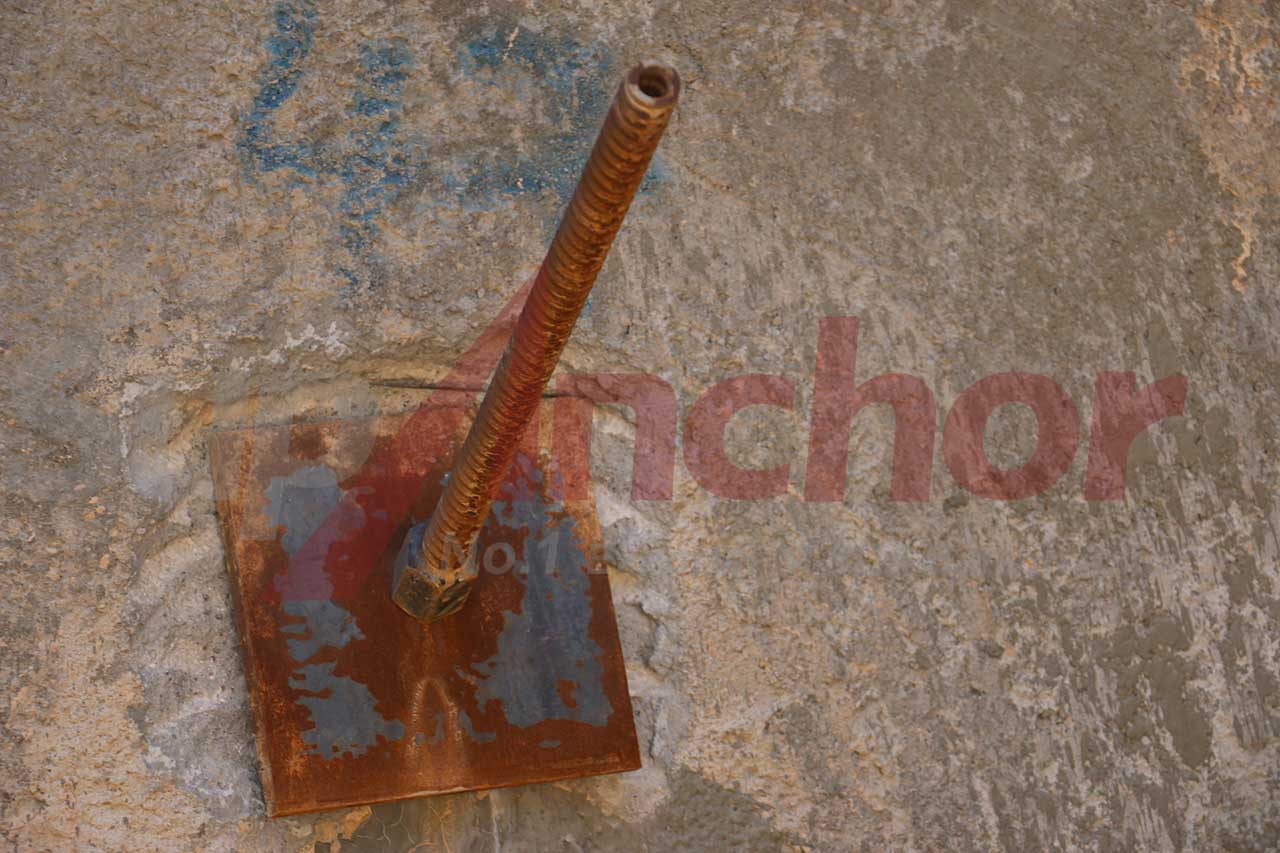

The self drilling anchor system employs a ribbed hollow steel bar that embodies the "3-in-1 principle," serving as a sacrificial drilling rod, injection tube, and reinforcing bar. This design allows for simultaneous drilling and grouting, significantly cutting construction time and labor intensity. The R thread is standardized under ISO 10208 and ISO 1720, ensuring quick on-site connections and compatibility across projects.

Key technical parameters highlight the system's robustness. Here are selected models from the R thread series, showcasing critical data for engineering applications:

| Model | Outside Diameter (mm) | Internal Diameter (mm) | Ultimate Load (kN) | Weight (kg/m) |

|---|---|---|---|---|

| R25N/12 | 25 | 12 | ≥200 | 2.30 |

| R32L/22 | 32 | 22 | ≥250 | 2.75 |

| R32S/15 | 32 | 15 | ≥360 | 4.00 |

| R38N/21 | 38 | 21 | Data Varies | Data Varies |

| R51/1000 | 51 | Varies | ≥1000 | Data Varies |

These parameters enable engineers to select anchors based on specific load requirements and soil conditions, optimizing safety and performance. The hollow bar anchor design facilitates efficient grout flow, enhancing bond strength and stability in challenging terrains. Anti-corrosion options, including hot-dip galvanizing, SupCoating, and stainless steel, extend service life in diverse environments, from dry soils to coastal areas.

The self drilling anchor bolt system is versatile, finding use in critical infrastructure projects. In tunneling engineering, it supports tunnel face stabilization, forepoling, and surrounding rock reinforcement, ensuring worker safety and project continuity. For ground engineering, applications include slope stabilization, foundation reinforcement, and retaining wall support, preventing soil collapse in urban developments. Other geotechnical projects, such as emergency repairs or soft ground support, benefit from the rapid installation and reliability of this drill-and-grout bolt system.

This geotechnical reinforcement system contributes significantly to global infrastructure safety and efficiency. By reducing construction time and labor costs, it supports sustainable development in mining, transportation, and urban expansion. The ability to handle unconsolidated soils minimizes delays and accidents, aligning with industry standards for risk management. SupAnchor's solutions are integral to projects worldwide, from European rail networks to American highway upgrades, fostering economic growth and public safety.

SupAnchor's commitment to R&D and innovation is evident in the R thread series' design and certifications. Adherence to ISO standards ensures product quality and interoperability, while ongoing research focuses on enhancing load capacities and environmental adaptability. The brand's collaborative approach with engineering firms has led to tailored solutions for complex projects. With a track record of 39 million meters deployed, SupAnchor exemplifies professionalism and reliability in the soil nail system manufacturer sector.

As infrastructure demands grow, SupAnchor's self drilling anchor system sets new benchmarks for safety and efficiency. By integrating drilling and grouting, this hollow bar anchor offers a streamlined solution for modern geotechnical challenges, reinforcing SupAnchor's position as a ground anchor bolt factory leader. For more updates on innovative engineering solutions, visit SupAnchor.com.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.