In the demanding terrain of the European Alps, a major railway expansion project has successfully leveraged SupAnchor's advanced self drilling anchor system to overcome significant geological challenges. This industry news report delves into the project background, technical applications, and broader implications for geotechnical engineering, focusing on the role of innovative anchor bolt systems in modern civil infrastructure.

The project involved stabilizing a steep, unstable slope along a key railway route, characterized by loose soil, rock fractures, and high groundwater levels. With a scale spanning over 500 meters of embankment, engineers faced risks of landslides and structural failures. SupAnchor's self drilling anchor system was selected for its efficiency in foundation support and slope stabilization, offering a drill-and-grout bolt solution that minimized disruption and enhanced safety. This application underscores the growing reliance on geotechnical reinforcement systems in challenging environments across Europe and North America.

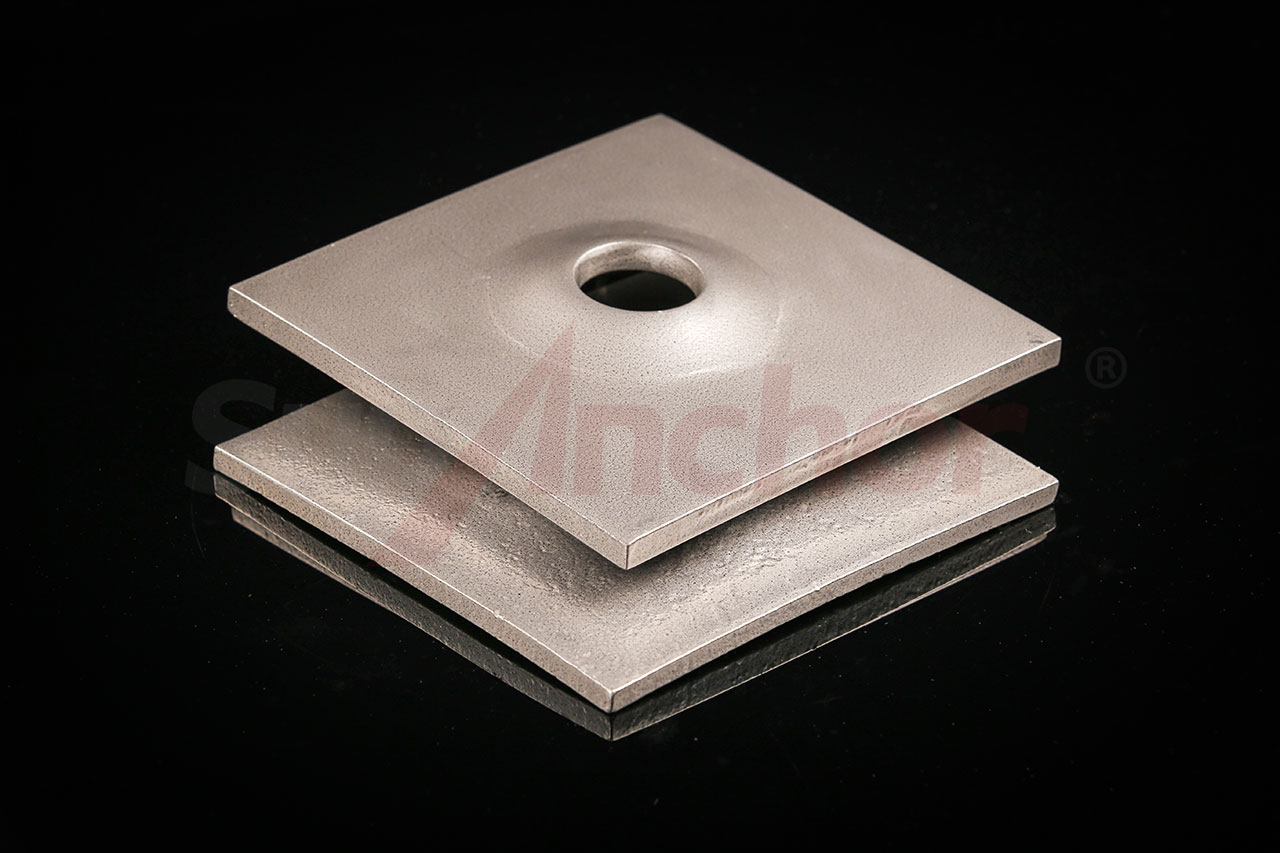

The construction site image depicts workers installing hollow bar anchors using specialized machinery, showcasing the seamless integration of SupAnchor's products. The self drilling anchor bolt system allows for simultaneous drilling and grouting, reducing installation time in unstable substrates. Key product parameters, which directly address site-specific challenges like load-bearing capacity and corrosion resistance, are detailed below:

| Parameter | Value |

|---|---|

| Tensile Strength | 600 MPa |

| Diameter | 32 mm |

| Length | Up to 12 meters |

| Corrosion Protection | Hot-dip Galvanized |

| Type | Hollow Bar Anchor |

These specs enable the self drilling anchor system to provide robust ground stabilization in soft soils and fractured rock, with the hollow design facilitating efficient grout injection for enhanced bonding. The geotechnical reinforcement system's adaptability makes it ideal for applications like retaining walls and tunneling, where precision and durability are paramount.

The success of this project highlights several key trends in the industry. With aging infrastructure and urbanization driving demand for safe, efficient solutions, technologies like self drilling anchor bolts are becoming standard in civil engineering. Projects worldwide, from underground mining to transportation networks, increasingly rely on ground anchor bolt systems for slope stabilization and foundation support. This case study aligns with global efforts to improve geotechnical safety, emphasizing the role of innovative products from manufacturers like SupAnchor in mitigating risks and enhancing project timelines.

SupAnchor has established itself as a leader in the soil nail system manufacturer space, with ISO 9001 certifications ensuring quality and reliability. The company's direct supply model from its SDA bolt factory supports collaborative partnerships with engineers and contractors worldwide. By emphasizing professionalism, innovation, and collaboration, SupAnchor delivers ground stabilization anchor systems that meet the evolving needs of geotechnical engineering. This project exemplifies their commitment to providing self drilling bolt for civil engineering applications, with a portfolio spanning rock bolt for underground mining and anchor bolt system for geotechnical engineering projects across continents.

The integration of SupAnchor's products into this European rail project not only solves immediate technical challenges but also sets a benchmark for future applications. As the industry moves towards smarter, more sustainable solutions, the self drilling anchor for retaining walls and other geotechnical systems will play a crucial role in shaping resilient infrastructure globally.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.