In the rugged terrain of the European Alps, a major tunneling project is underway to expand transportation networks, facing complex geotechnical challenges such as unstable rock formations and high groundwater levels. SupAnchor, a leading soil nail system manufacturer, has deployed its advanced self drilling anchor system to provide robust foundation support, ensuring project stability and safety. This industry news report delves into the technical applications, industry relevance, and innovative solutions driving modern geotechnical engineering.

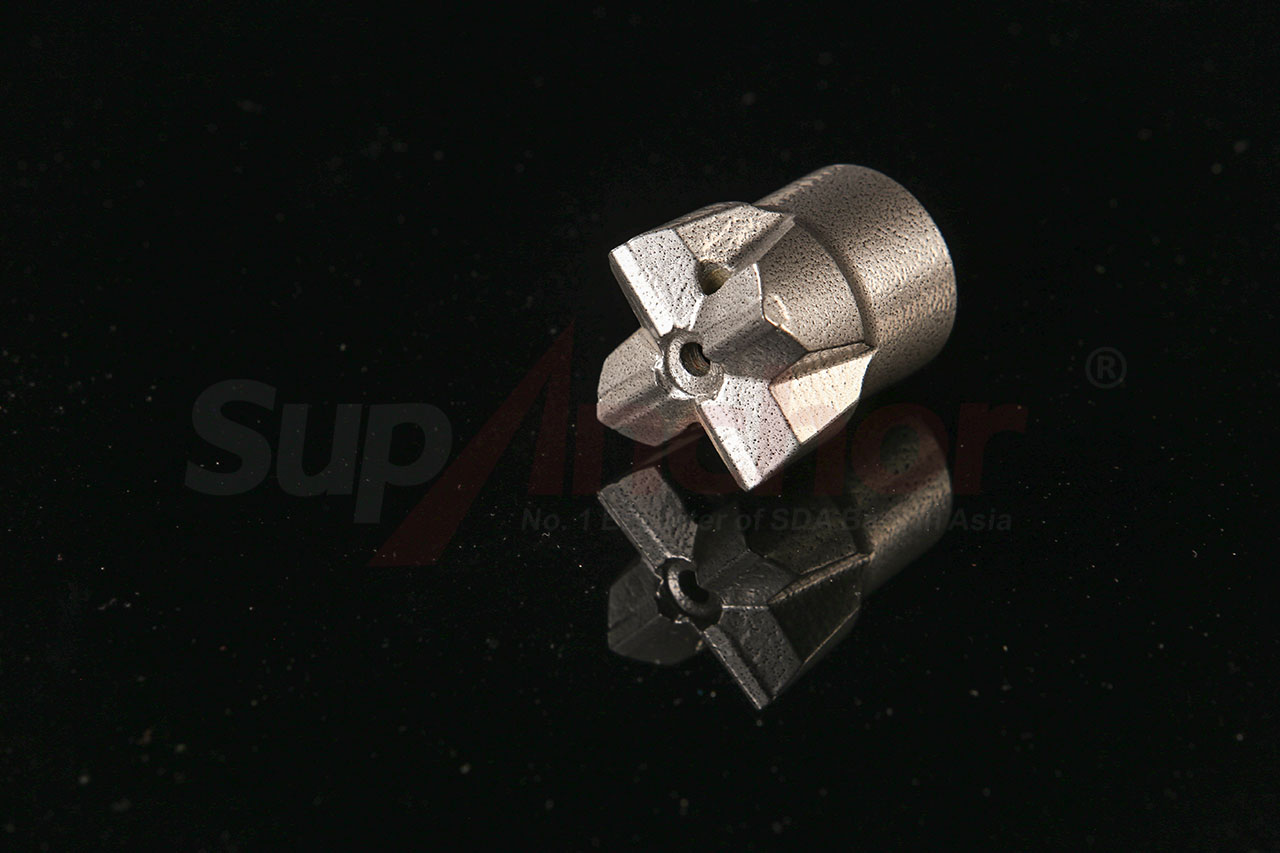

The construction scene depicted in the image showcases SupAnchor's hollow bar anchor system in action, where crews install self drilling bolts to reinforce tunnel walls and prevent collapses. This ground stabilization anchor system integrates seamlessly with drill-and-grout techniques, addressing site-specific issues like soft soil and seismic activity. Key product parameters, derived from SupAnchor's specifications, highlight the technical prowess of their self drilling anchor for retaining walls and other civil engineering applications.

| Parameter | Value |

|---|---|

| Tensile Strength | 550 kN |

| Diameter | 32 mm |

| Length | Up to 15 m |

| Corrosion Protection Type | Hot-Dip Galvanized |

| Application | Tunneling and Slope Stabilization |

These specs enable the self drilling bolt for civil engineering to penetrate difficult strata without pre-drilling, reducing installation time and enhancing load-bearing capacity. The corrosion protection ensures durability in harsh alpine environments, while the high tensile strength supports heavy structural loads. SupAnchor's ground anchor bolt factory emphasizes precision in manufacturing, with this micropile hollow bar anchor system offering direct supply advantages for global projects.

The project aligns with broader trends in infrastructure development, where geotechnical reinforcement systems are crucial for safe and sustainable construction. As urbanization accelerates and climate change impacts slope stability, technologies like SupAnchor's anchor bolt system for geotechnical engineering become indispensable. This self drilling anchor system is not only pivotal for tunneling but also for applications in underground mining, where rock bolt for underground mining ensures worker safety and operational continuity.

SupAnchor's role extends beyond single projects, contributing to a resilient infrastructure ecosystem. Their self drilling anchor bolt technology supports critical sectors such as mining, where rock bolts mitigate collapse risks, and civil engineering, where retaining walls require robust anchoring. This industry outlook underscores the importance of continuous innovation in geotechnical engineering to address evolving challenges.

SupAnchor stands out as a professional leader in the geotechnical field, with ISO certifications ensuring high-quality standards across their product range, including the self drilling anchor system and related components. Their innovative approach integrates research and development to optimize hollow bar anchor designs, reducing environmental impact while improving performance. The company's collaborative ethos involves partnering with global clients to tailor solutions, from slope stabilization to large-scale tunneling projects.

Notable achievements include deployments in diverse geographies, demonstrating the versatility of their ground anchor bolt systems. SupAnchor's commitment to "Professional, Innovative, Collaborative" values is evident in their customer-centric services and technical support, which enhance project outcomes. As a soil nail system manufacturer, they prioritize safety and efficiency, ensuring that their products, like the self drilling anchor for retaining walls, meet stringent industry benchmarks.

In conclusion, SupAnchor's self drilling anchor system exemplifies cutting-edge geotechnical engineering, addressing complex site challenges with precision and reliability. This project highlights the critical role of such technologies in modern infrastructure, paving the way for safer and more sustainable development worldwide. For more insights into ground stabilization anchor systems and industry updates, visit SupAnchor's official resources.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.