In response to growing global infrastructure demands and the need for long-lasting, corrosion-resistant materials, SupAnchor has unveiled the SupAnchor® GFRP Reinforcement Rebar. This innovative product, developed as a high-performance alternative to traditional steel reinforcement, is set to revolutionize construction in harsh environments such as coastal areas, bridges, and industrial plants. With increasing challenges from saltwater exposure and chemical corrosion, engineers are turning to advanced solutions like this GFRP rebar to ensure structural integrity and reduce maintenance costs.

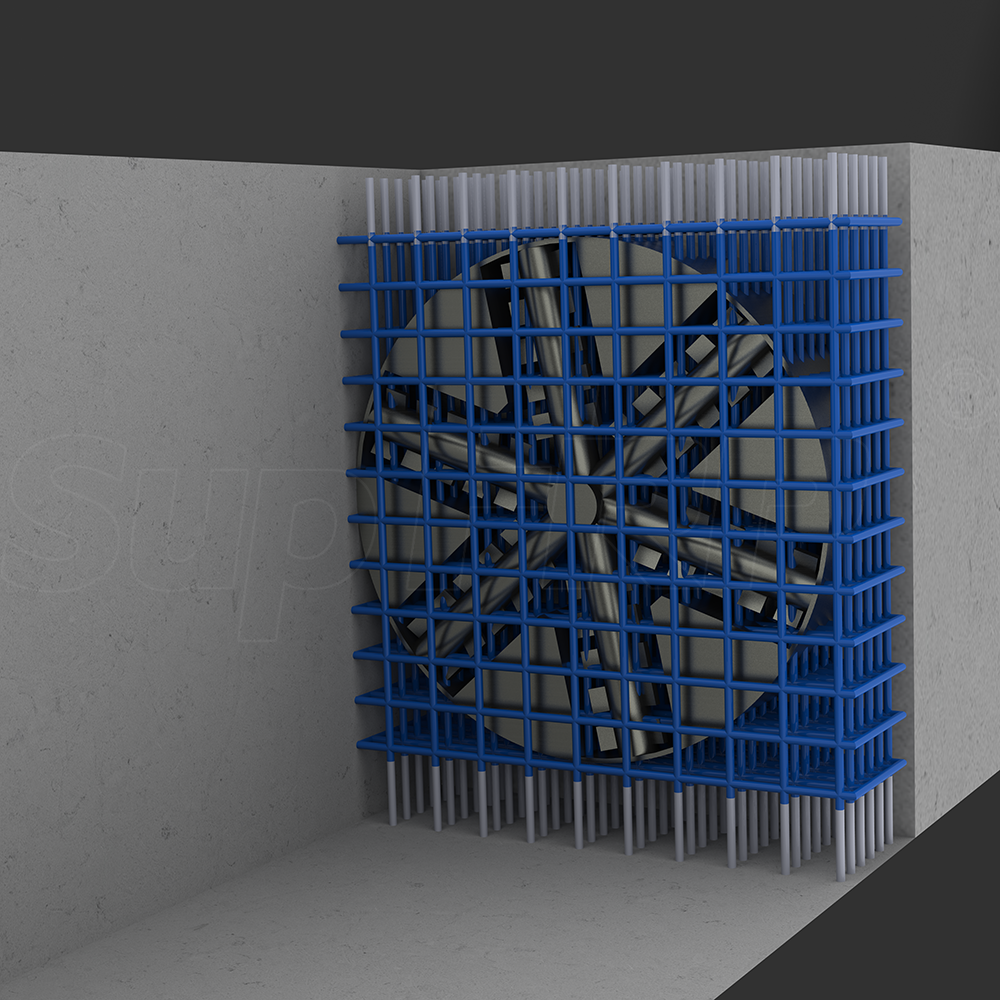

The SupAnchor® GFRP Reinforcement Rebar is manufactured using high-quality corrosion-resistant resin and fiberglass, offering superior durability and adaptability. It can be produced in various shapes in the factory to meet diverse construction needs, making it ideal for applications ranging from soft-eye excavation to sea walls and precast elements. As a leader in geotechnical reinforcement systems, SupAnchor leverages its expertise in products like the self drilling anchor system to drive innovation in reinforcement technology.

The SupAnchor® GFRP Reinforcement Rebar boasts a range of technical advantages that address common engineering challenges. Key features include high tensile strength of up to 1000 MPa, excellent bonding with concrete, and non-conductive, non-magnetic properties, which enhance safety and performance in electrical and sensitive environments. The product's high corrosion resistance ensures permanent application without degradation, reducing lifecycle costs and improving sustainability in infrastructure projects.

To illustrate the product's capabilities, here is a table summarizing key parameters for selected diameters, highlighting how these specs solve engineering challenges such as load-bearing requirements and weight optimization:

| Diameter (Model) | Guaranteed Tensile Load (kN) | Tensile Strength (MPa) | Weight (kg/m) |

|---|---|---|---|

| ReB-10 (11.5mm) | 79 | 1000 | 0.2 |

| ReB-16 (18mm) | 201 | 1000 | 0.50 |

| ReB-25 (28mm) | 491 | 1000 | 1.20 |

| ReB-36 (41mm) | 867 | 850 | 2.65 |

These parameters demonstrate the product's adaptability to various load conditions, from light-duty applications to heavy infrastructural buildings. The easy cutting and handling features further streamline construction processes, reducing labor time and costs. By integrating this GFRP rebar, projects can achieve enhanced geotechnical safety and longevity, similar to the benefits offered by SupAnchor's self drilling anchor bolt systems in ground reinforcement.

The SupAnchor® GFRP Reinforcement Rebar is designed for a wide array of applications, making it a versatile solution for modern construction needs. Primary uses include:

This product aligns with global trends toward sustainable and resilient infrastructure, particularly in regions prone to environmental stressors. By reducing the need for frequent replacements and maintenance, it offers significant market value in terms of cost savings and environmental impact. The self drilling anchor system and hollow bar anchor technologies from SupAnchor complement this rebar, providing a comprehensive geotechnical reinforcement system for diverse engineering challenges.

SupAnchor's introduction of the GFRP Reinforcement Rebar underscores its commitment to innovation and quality in the construction industry. With a strong focus on research and development, the company holds ISO certifications and has successfully implemented projects worldwide, from tunneling and mining to large-scale infrastructural developments. This product exemplifies SupAnchor's professional approach, leveraging advanced materials science to address real-world engineering problems.

The brand's collaborative ethos is evident in its partnerships with engineers and contractors to tailor solutions for specific site conditions. By offering products like the drill-and-grout bolt and this GFRP rebar, SupAnchor positions itself as a key player in enhancing geotechnical safety and infrastructure durability. As a soil nail system manufacturer and ground anchor bolt factory, the company continues to push boundaries, ensuring that its innovations meet the evolving demands of European and American markets.

In conclusion, the SupAnchor® GFRP Reinforcement Rebar represents a significant advancement in reinforcement technology, driven by SupAnchor's core values of professionalism, innovation, and collaboration. As infrastructure projects become more complex and environmentally demanding, this product offers a reliable, high-performance alternative that enhances durability and reduces lifecycle costs. With its integration into global projects, SupAnchor is set to influence the future of construction, reinforcing its reputation as a leader in geotechnical reinforcement systems.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.