In a recent coastal infrastructure project in Europe, engineers faced significant challenges with corrosion and electrical hazards in reinforced concrete structures. SupAnchor® stepped in with its innovative GFRP Mesh, providing a durable and safe alternative to traditional metal meshes. This product news highlights how SupAnchor's geotechnical reinforcement system, including elements like the self drilling anchor bolt, integrates with advanced materials like GFRP Mesh to address complex engineering needs.

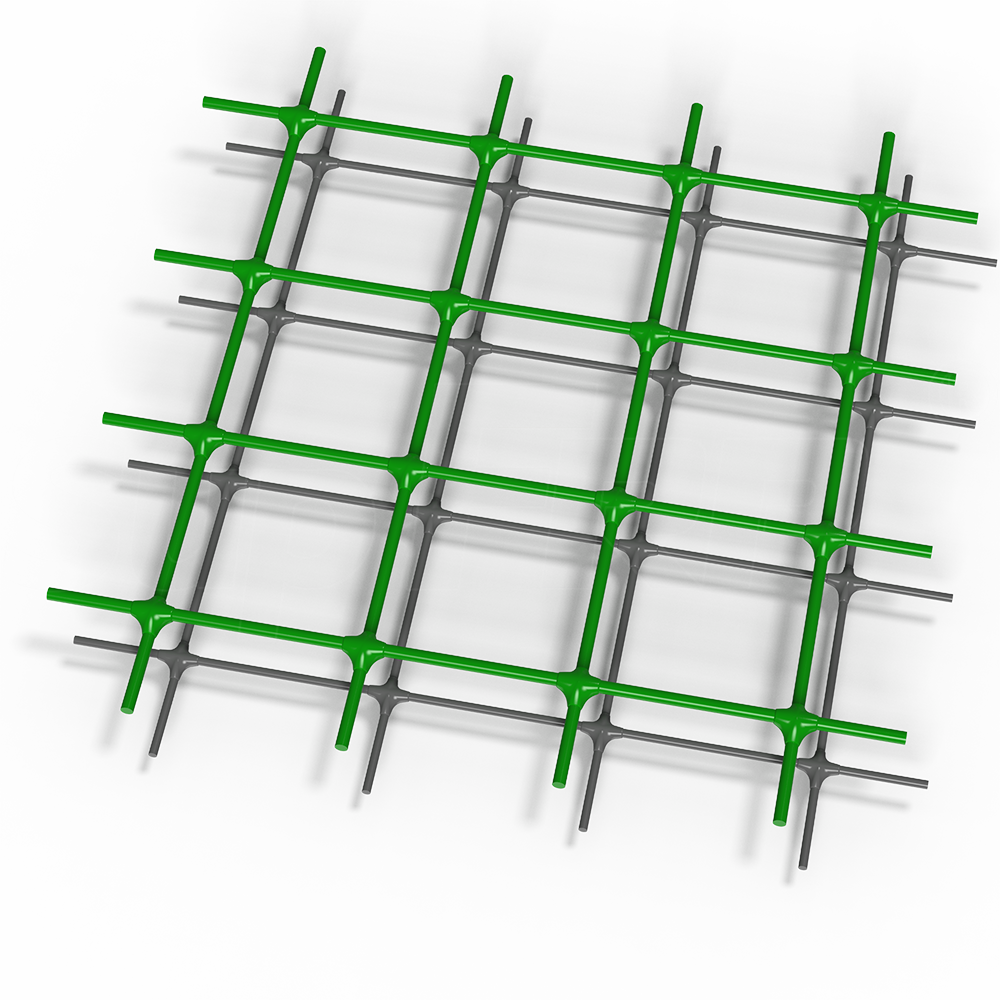

The SupAnchor® GFRP Mesh is assembled from longitudinal and transverse glass fiber reinforced polymer (GFRP) rods, with joints fixed by impregnated polymer yarn for reliability. This design ensures high strength and flexibility, making it suitable for various site processes where lightweight and easy construction are critical. Key parameters from the product introduction, such as rod diameter and jointing load, directly address engineering challenges like corrosion and conductivity. For instance, in a tunneling project, the non-conductive properties of the mesh enhance safety near electrical installations, while its corrosion resistance extends the lifespan of structures in humid environments.

To illustrate the technical specs, here is a table summarizing the data for different mesh types:

| Mesh Type | Rod Diameter (mm) | Jointing Load (kN) | Grid Size (mm) |

|---|---|---|---|

| M4 | 4 | 2 | 100x100, 150x1500* |

| M6 | 6 | 3 | 100x100, 150x1500* |

| M8 | 8 | 5 | 100x100, 150x1500* |

*Other grid sizes are available upon request. These parameters enable customization for specific project needs, such as in mining operations where high strength is essential for ground stabilization.

The GFRP Mesh finds extensive use in key applications, including roof and wall protection, repair of concrete structures, flat slab construction, and highway overlays. For example, in highway projects across the United States, the mesh's lightweight nature reduces installation time and costs, while its non-magnetic properties prevent interference with nearby equipment. This aligns with global trends in infrastructure development, where materials like hollow bar anchors and drill-and-grout bolts are increasingly paired with composite meshes for enhanced geotechnical safety.

These features contribute to the mesh's market value by offering long-term durability and reduced maintenance, making it a cost-effective solution for public and private sectors.

SupAnchor® has established itself as a leader in the geotechnical reinforcement industry through continuous R&D and innovation. With ISO certifications and a portfolio of global projects, the company emphasizes a collaborative approach, working closely with engineers to develop tailored solutions. The GFRP Mesh is part of a broader product line that includes the self drilling anchor bolt and soil nail system manufacturer offerings, showcasing SupAnchor's commitment to professional and innovative practices. By integrating this mesh into projects, SupAnchor reinforces its brand message of being a reliable partner in construction safety and efficiency.

In conclusion, the SupAnchor® GFRP Mesh represents a significant advancement in construction materials, addressing critical needs in corrosion resistance and electrical safety. As infrastructure demands grow in Europe and America, products like this mesh, along with related systems such as the ground anchor bolt factory outputs, will play a vital role in sustainable development. SupAnchor's dedication to quality and adaptability ensures that it remains at the forefront of the industry, driving progress through innovative reinforcement solutions.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.