In the face of increasing infrastructure demands and harsh environmental conditions, such as coastal erosion in European port cities or corrosive industrial settings in North America, construction projects require durable and reliable reinforcement solutions. SupAnchor®, a leader in geotechnical and construction innovation, has responded with the introduction of its SupFRP® GFRP Reinforcement Rebar. This product serves as a high-performance alternative for concrete internal reinforcement, designed to overcome challenges like corrosion, maintenance costs, and structural longevity in critical applications such as bridge decks, sea walls, and industrial plants.

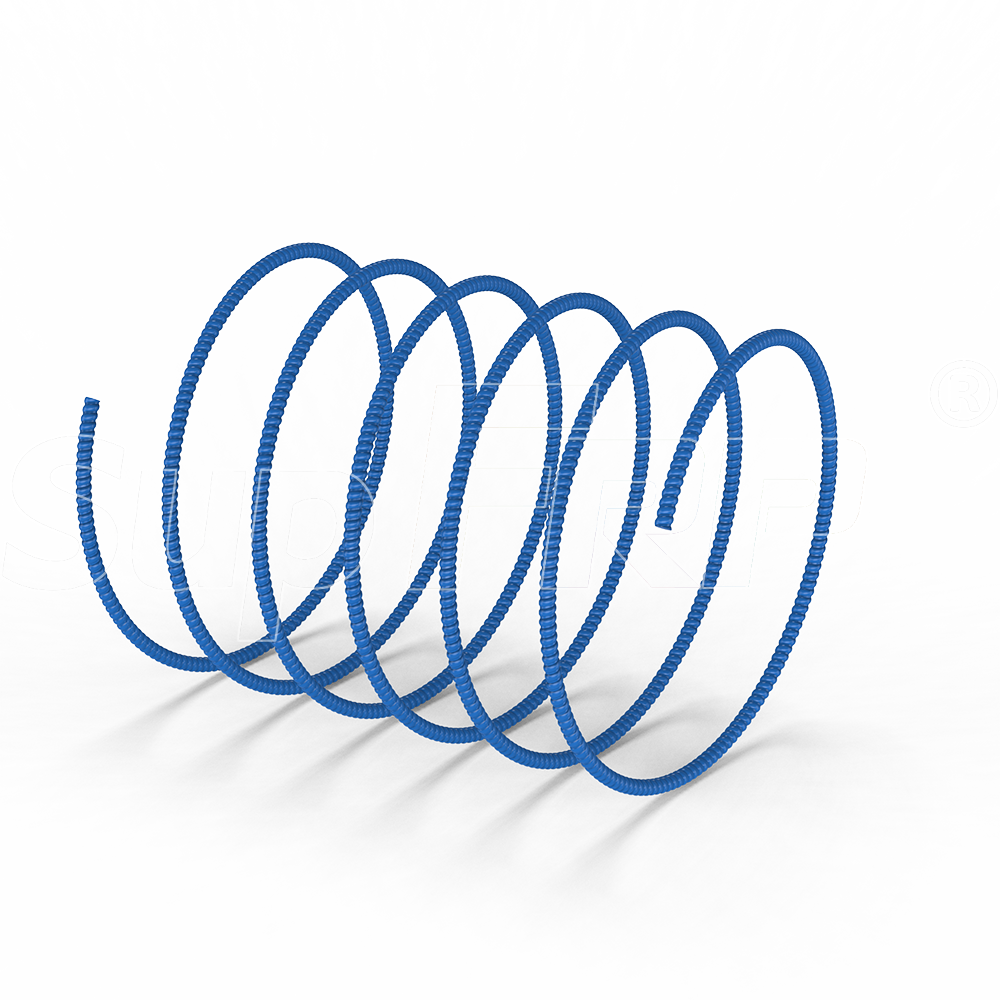

The SupFRP® GFRP Reinforcement Rebar is manufactured using high-quality corrosion-resistant resin and fiberglass materials, enabling it to be produced in various shapes to meet diverse construction needs. Key advantages include high corrosion resistance for permanent application, excellent bonding with concrete, high tensile strength, non-conductive and non-magnetic properties, easy cutting, cost-effectiveness, a wide range of shapes, and easy handling. These features make it ideal for scenarios where traditional steel rebar might fail due to rust or electromagnetic interference.

To illustrate its capabilities, here are some technical specifications for selected models, highlighting how they address engineering challenges:

| Model | Outside Diameter (mm) | Guaranteed Tensile Load (kN) | Tensile Strength (MPa) | Weight (kg/m) |

|---|---|---|---|---|

| ReB-10 | 11.5 | 79 | 1000 | 0.2 |

| ReB-20 | 23 | 314 | 1000 | 0.79 |

| ReB-30 | 34 | 636 | 900 | 1.88 |

These parameters demonstrate the product's robust performance, with tensile strengths ranging from 800 to 1000 MPa and consistent tensile E-modulus of 50 GPa across most sizes. The guaranteed tensile load scales with diameter, ensuring reliable load-bearing capacity for various structural needs. For instance, in soft-eye excavation or bridge deck applications, the high tensile strength and corrosion resistance prevent failure and reduce long-term maintenance, while the non-conductive nature is crucial in environments with electrical hazards.

The versatility of SupAnchor's GFRP reinforcement rebar allows it to be deployed across multiple high-stakes construction domains. Primary applications include:

This broad applicability underscores the product's role in advancing construction methodologies, particularly in regions with stringent environmental regulations or challenging geological conditions.

SupAnchor's introduction of GFRP reinforcement rebar aligns with global trends toward sustainable and resilient infrastructure. By offering a solution that reduces corrosion-related failures, the product contributes to lower lifecycle costs and enhanced safety in projects ranging from urban developments to remote mining operations. The industry value is evident in its potential to replace traditional steel rebar in corrosion-prone areas, thereby minimizing downtime and repair expenses.

SupAnchor's commitment to innovation is reflected in its rigorous research and development processes, which have led to ISO-certified manufacturing standards and a track record of successful global projects. The brand emphasizes a collaborative approach, working with engineers and contractors to tailor solutions for specific challenges. This professional ethos, combined with a focus on technological advancement, positions SupAnchor as a key player in the geotechnical reinforcement system market.

In summary, the SupFRP® GFRP Reinforcement Rebar represents a significant step forward in construction technology, addressing critical needs for durability, efficiency, and cost-effectiveness. As infrastructure demands grow worldwide, products like this will be essential for building resilient and long-lasting structures. SupAnchor continues to lead with a message of professionalism, innovation, and collaboration, ensuring that its solutions meet the evolving needs of the construction industry.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.