In the rugged Swiss Alps, a high-stakes geotechnical project is stabilizing slopes for a new high-speed railway, where SupAnchor's self-drilling anchor system has proven indispensable. This initiative addresses complex geology, including unstable rock formations and steep inclines, common in European infrastructure developments. SupAnchor's role focuses on foundation support and slope stabilization, ensuring long-term safety and efficiency. The project, spanning several kilometers, highlights the growing reliance on advanced geotechnical solutions in challenging environments, with SupAnchor's innovations at the forefront.

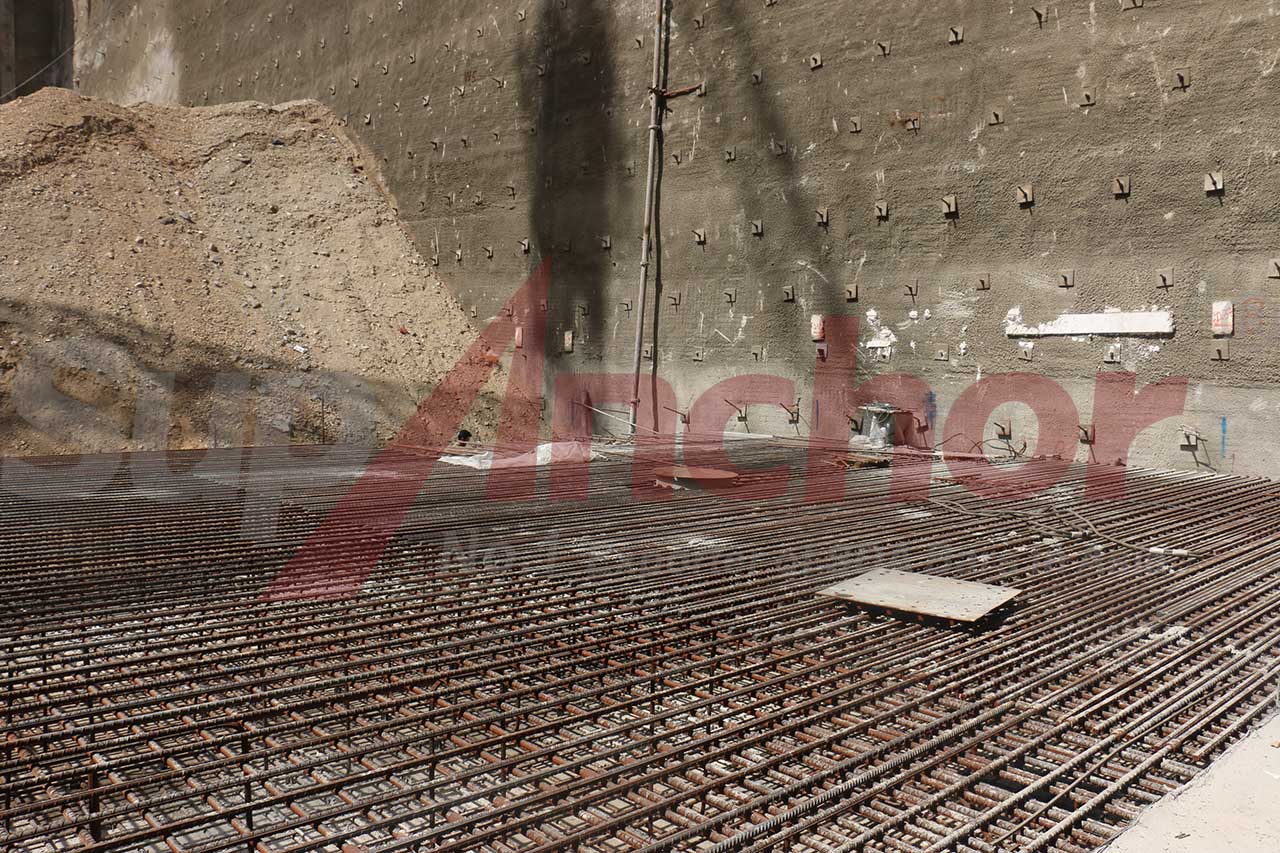

The construction site, depicted in the image, shows SupAnchor's self-drilling anchor bolts being installed into rocky slopes, a process that combines drilling and grouting in one step for enhanced efficiency. These hollow bar anchors are designed to tackle site-specific challenges like variable soil conditions and high water tables. Key product parameters, derived from SupAnchor's specifications, include tensile strength, diameter, length, and corrosion protection, all tailored to meet the demands of this alpine project. The self-drilling anchor bolt system allows for rapid deployment, reducing labor costs and minimizing environmental disruption. Engineers on-site report that the drill-and-grout bolt method has streamlined operations, providing immediate reinforcement without the need for additional equipment.

| Parameter | Value |

|---|---|

| Tensile Strength | 550 MPa |

| Diameter | 32 mm |

| Length | 6 m |

| Corrosion Protection | Hot-Dip Galvanized |

These specifications ensure the anchors withstand extreme loads and corrosive alpine conditions, directly addressing project challenges such as rock instability and erosion. For instance, the high tensile strength prevents failure under seismic activity, while the corrosion protection extends the system's lifespan in wet environments. SupAnchor, as a leading soil nail system manufacturer, emphasizes that these parameters are customizable, reflecting their commitment to tailored solutions for geotechnical reinforcement systems. The use of micropile hollow bar anchors in this context demonstrates their versatility, often applied in retaining walls and underground mining scenarios.

The adoption of SupAnchor's ground stabilization anchor system aligns with global trends in infrastructure development, where safety and sustainability are paramount. In Europe and North America, increasing investments in transportation networks drive demand for reliable geotechnical engineering solutions. This project exemplifies how self-drilling bolts for civil engineering contribute to safer tunneling and slope stabilization, reducing risks in urban and remote areas alike. The geotechnical reinforcement system employed here is part of a broader shift towards innovative methods that enhance project timelines and cost-efficiency. For example, rock bolts for underground mining have seen similar advancements, improving safety in extractive industries. SupAnchor's SDA bolt factory direct supply model ensures consistent quality, supporting large-scale projects worldwide. As climate change intensifies geological hazards, the role of ground anchor bolt factories in providing robust solutions becomes increasingly critical, with SupAnchor leading in certifications and compliance.

SupAnchor's reputation as a professional and innovative ground anchor bolt factory is built on decades of experience and ISO-certified processes. Their self-drilling anchor for retaining walls and other applications underscores a collaborative approach, working closely with engineers to address site-specific needs. The company's global portfolio includes projects in tunneling, mining, and transportation, where their anchor bolt system for geotechnical engineering has delivered measurable results. Highlights of SupAnchor's value proposition include:

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.