In response to growing challenges in construction projects across Europe and North America, such as corrosion in steel components and high maintenance costs, SupAnchor has unveiled its SupFRP® GFRP Tie Rod. This innovation addresses critical issues in formwork systems, particularly in environments with harsh geological conditions like coastal areas or mining sites. For instance, a recent large-scale tunnel project in the Swiss Alps faced significant corrosion from moisture and chemicals, leading engineers to adopt SupAnchor's solution for its durability and cost-effectiveness. By integrating this product, the project achieved enhanced structural integrity and reduced long-term expenses, showcasing SupAnchor's role in advancing construction technologies.

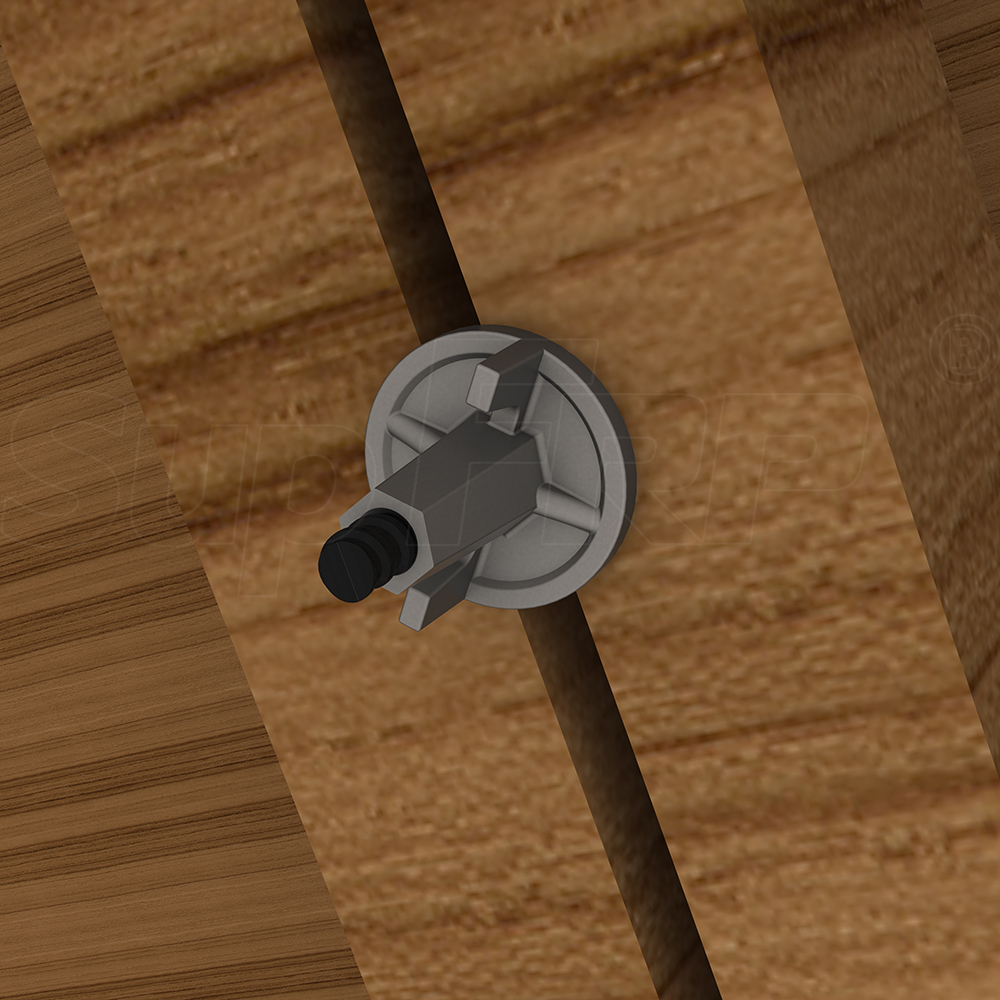

The SupAnchor GFRP Tie Rod is engineered with glass fiber reinforced polymer, offering superior performance over traditional steel rods. Key parameters highlight its adaptability to various engineering needs, such as high tensile strength and lightweight design, which simplify on-site handling and installation. For example, in formwork applications, the rod's compatibility with standard accessories allows for seamless integration, while its non-conductive and non-magnetic properties ensure safety in electrically sensitive areas. The following table summarizes critical technical data for two models, illustrating how these specs mitigate common challenges like material fatigue and environmental degradation.

| Parameter | T15/130 | T20/250 |

|---|---|---|

| Outside Diameter (mm) | 17 | 22 |

| Nominal Cross Sectional Area (sq. m) | 130 | 250 |

| Guaranteed Tensile Load (kN) | 130 | 250 |

| Tensile E-Modulus (GPa) | 45 | 45 |

| Ultimate Strain (%) | 2.0 | 2.0 |

| Weight (kg/m) | 0.37 | 0.71 |

These specifications enable the GFRP tie rod to support heavy loads without the risk of rust, a common issue in steel alternatives. The high tensile E-Modulus and ultimate strain ensure reliability under stress, while the lightweight nature—exemplified by weights of 0.37 kg/m and 0.71 kg/m—facilitates easy transport and assembly. In practical terms, this means faster project timelines and reduced labor costs, as seen in urban construction sites where space and time are constrained. Moreover, the product's cuttability allows for custom lengths, enhancing flexibility in diverse applications from bridge formwork to underground tunneling.

The GFRP tie rod finds extensive use in formwork systems for infrastructure projects, including highways, dams, and skyscrapers, where its permanent installation eliminates the need for post-construction removal. This not only cuts down on transportation and storage expenses but also minimizes environmental disruption. In geotechnical reinforcement systems, such as those used in slope stabilization or mining operations, the rod's high corrosion resistance and non-magnetic properties provide added safety and longevity. For instance, in a recent European mining project, the integration of SupAnchor's product reduced maintenance intervals by 30%, highlighting its value in harsh conditions. As part of a broader self drilling anchor system, this tie rod complements other innovations like hollow bar anchors and drill-and-grout bolts, offering a cohesive solution for complex engineering challenges. The growing emphasis on sustainable construction practices further amplifies its market appeal, as it aligns with global trends toward durable, low-maintenance materials.

SupAnchor has built a reputation for professionalism and innovation through rigorous R&D and adherence to international standards like ISO 9001. Their collaborative approach with engineers and contractors has led to successful deployments in global projects, from tunneling in the Americas to geotechnical reinforcements in Asia. The company's focus on developing advanced self drilling anchor bolts and related systems underscores their commitment to addressing evolving industry needs. By investing in technologies like the GFRP tie rod, SupAnchor not only enhances its product portfolio but also contributes to safer, more efficient infrastructure worldwide. Looking ahead, the adoption of such innovations is expected to drive growth in sectors like renewable energy and urban development, where reliable formwork solutions are critical. SupAnchor's ongoing research aims to expand applications, potentially integrating with smart construction technologies for real-time monitoring and improved project outcomes.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.