In the challenging geological conditions of a major European hydropower station, unstable slopes posed significant risks to construction timelines and safety. SupAnchor's Grade 75 self-drilling hollow anchor bars were deployed as a key solution, providing robust reinforcement to prevent landslides and ensure long-term stability. This innovative self drilling anchor system has demonstrated exceptional performance in harsh environments, aligning with the project's scale and complexity.

The installation process for the self drilling anchor bolt involved drilling directly into rocky substrates without pre-drilling, significantly reducing labor and time. Engineers highlighted the need for high tensile strength and compatibility with existing grouting systems to address soil erosion and structural weaknesses. SupAnchor's bars met these demands with their advanced design, ensuring seamless integration into the geotechnical reinforcement system.

| Property | Value |

|---|---|

| Elongation | ≥ 6% |

| Yield Load | 147 kN (33 kips) |

| Ultimate Load | 196 kN (44 kips) |

| Weight | 2.6 kg/m (1.75 lbs/ft) |

| Thread Orientation | Left-hand |

These specifications, including the continuous T-thread design, enhance bond performance in concrete, effectively mitigating slippage and improving load distribution. The hollow bar anchor's compatibility with various drilling equipment allows for versatile applications, from slope stabilization to foundation reinforcement. By replacing solid threaded bars, this drill-and-grout bolt solution offers cost savings and faster deployment, crucial for time-sensitive projects.

SupAnchor's self drilling anchor system is widely used in tunneling, mining, and urban development projects across Europe and North America. For instance, in slope stabilization efforts, the bars provide reliable support against soil movement, reducing the risk of collapses in infrastructure like roads and buildings. The geotechnical reinforcement system's adaptability to different soil types makes it ideal for global initiatives aimed at enhancing public safety and economic resilience.

This innovation supports sustainable development by minimizing environmental disruption and improving project longevity. As infrastructure demands grow, the self drilling anchor bolt plays a pivotal role in ensuring that geotechnical challenges are met with efficient, scalable solutions.

SupAnchor has built a reputation for professionalism and innovation through extensive research and development, backed by ISO certifications that guarantee quality and reliability. Their global projects, including collaborations with engineering firms in Europe and America, showcase a commitment to advancing geotechnical safety. The company's focus on collaborative partnerships ensures that products like the hollow bar anchor are tailored to meet diverse project needs, reinforcing their message of being a trusted leader in the industry.

In summary, SupAnchor's Grade 75 self-drilling hollow anchor bars represent a significant advancement in geotechnical engineering, offering practical benefits for slope stabilization and beyond. Their integration into major projects underscores the value of innovative self drilling anchor systems in building safer, more resilient infrastructure worldwide.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

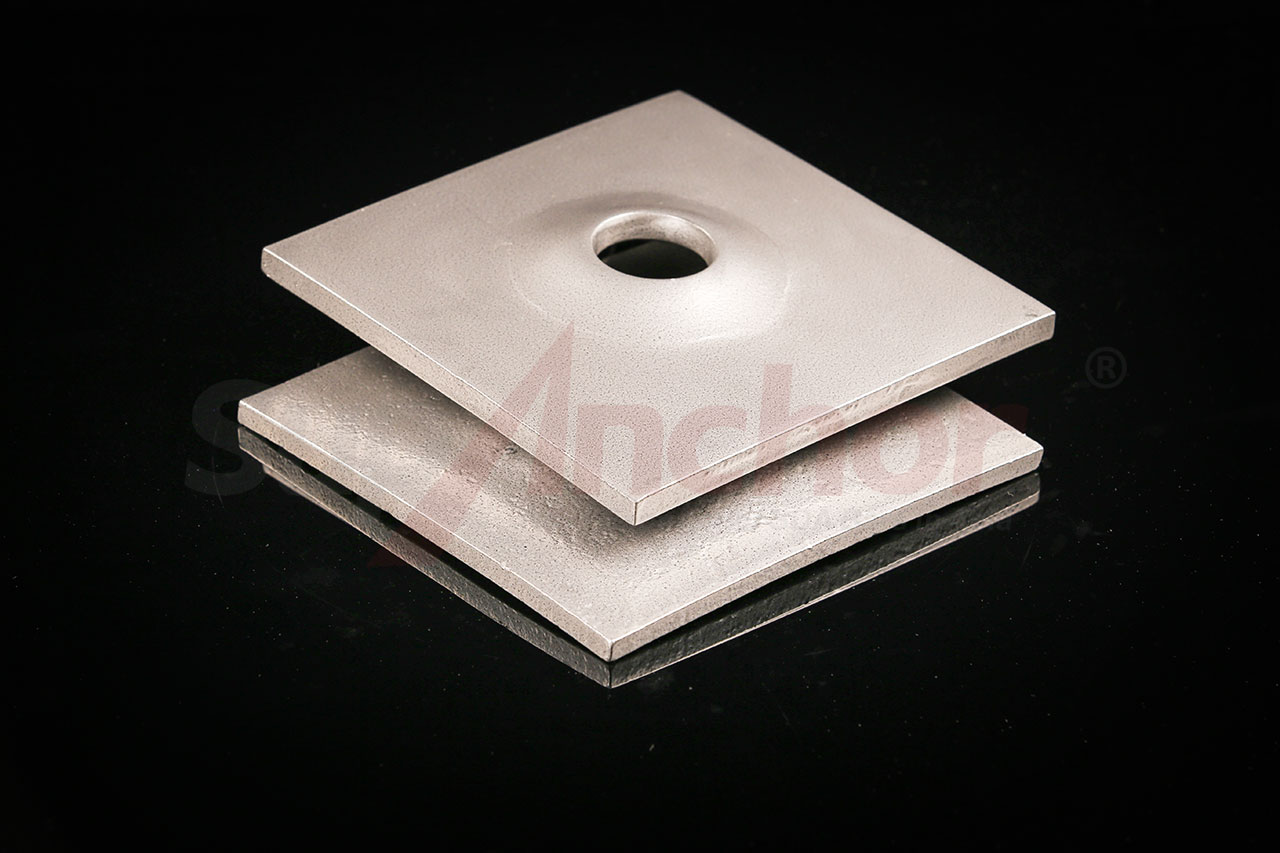

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.