In a recent large-scale bridge construction project in the Swiss Alps, engineers faced significant challenges with traditional steel tie rods, including high corrosion rates in harsh mountainous environments and escalating costs from frequent replacements. SupAnchor stepped in with its innovative GFRP Tie Rod, designed to address these issues by providing a permanent, corrosion-resistant solution that eliminates the need for removal, thereby cutting down on transportation and storage expenses. This development marks a step forward in optimizing formwork systems for complex geotechnical projects.

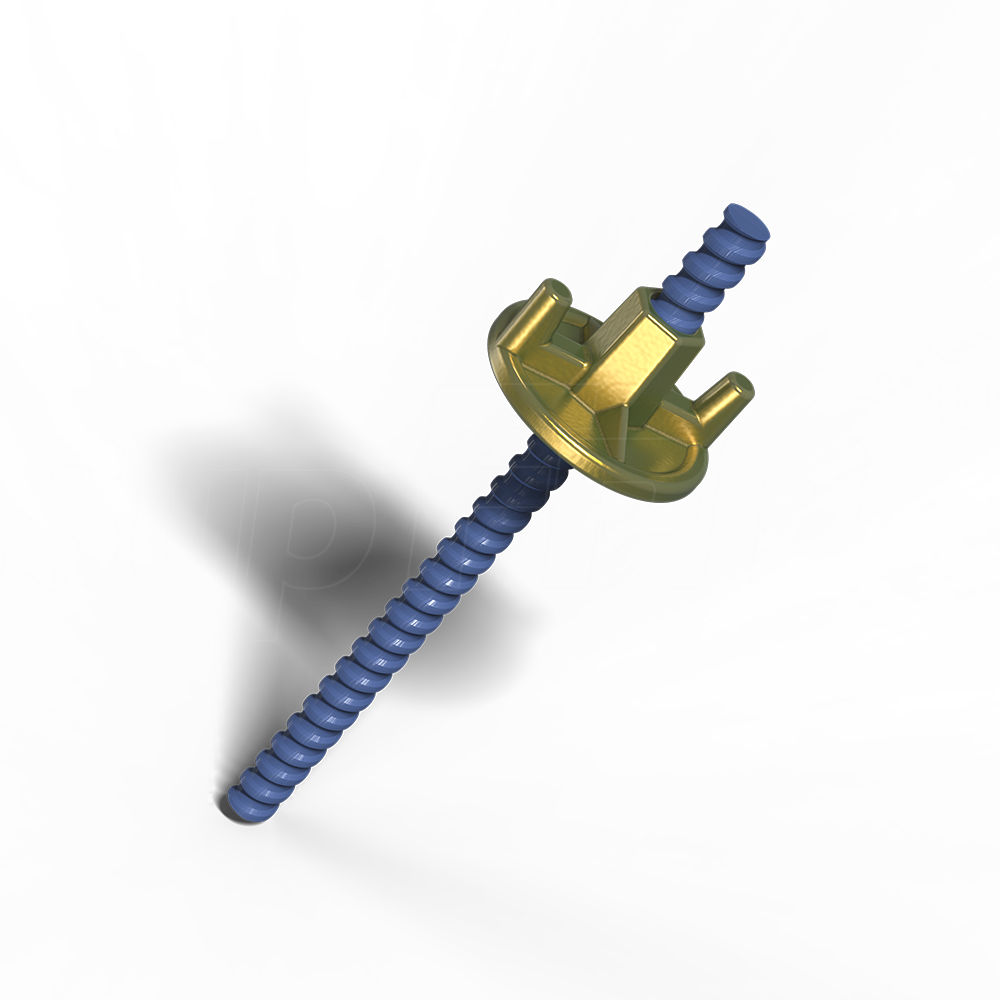

The SupAnchor GFRP Tie Rod is engineered to meet the rigorous demands of modern construction sites. Unlike conventional steel rods, it features high corrosion resistance, making it ideal for environments prone to moisture and chemical exposure. Key technical specifications include a guaranteed tensile load of up to 250 kN for the T20/250 model, an outside diameter of 22 mm, and a tensile modulus of 45 GPa, ensuring robust performance under stress. These parameters directly tackle common engineering challenges, such as reducing maintenance cycles and enhancing structural integrity in formwork applications. For instance, the rod's non-conductive and non-magnetic properties improve safety on sites with electrical hazards, while its easy handling and cuttability allow for quick adaptations during construction. The following table summarizes the technical data for two primary models, highlighting how these specs contribute to solving real-world problems like cost overruns and material waste.

| Model | Outside Diameter (mm) | Nominal Cross-Sectional Area (mm²) | Guaranteed Tensile Load (kN) | Tensile E-Modulus (GPa) | Ultimate Strain (%) | Weight (kg/m) | Length (m) |

|---|---|---|---|---|---|---|---|

| T15/130 | 17 | 130 | 130 | 45 | 2.0 | 0.37 | 2-11 |

| T20/250 | 22 | 250 | 250 | 45 | 2.0 | 0.71 | 2-11 |

By integrating these features, the GFRP Tie Rod not only supports efficient formwork but also complements SupAnchor's broader self drilling anchor system, enhancing overall geotechnical reinforcement systems. For example, in tunneling projects, the rod's high end loading and good bond force ensure stable concrete molds, reducing the risk of collapses and delays.

The GFRP Tie Rod finds extensive use in various formwork scenarios, from high-rise buildings to infrastructure like bridges and tunnels. Its permanent application means it remains embedded in the structure, which is particularly beneficial in mining and geotechnical projects where durability is paramount. This innovation aligns with global trends toward sustainable construction, as it minimizes material waste and lowers carbon footprints. In Europe and North America, where infrastructure aging is a concern, such advancements in geotechnical reinforcement systems help extend the lifespan of assets. The rod's compatibility with standard accessories further streamlines processes, making it a versatile choice for engineers seeking reliable solutions in challenging environments.

SupAnchor has built a reputation for professionalism and innovation through continuous research and development. The company holds ISO 9001 certification for quality management, underscoring its commitment to delivering high-performance products like the GFRP Tie Rod. Collaborations with international engineering firms have led to successful deployments in projects worldwide, from urban developments in the United States to remote mining sites in Australia. This collaborative approach ensures that solutions are tailored to local needs, reinforcing SupAnchor's role as a leader in the geotechnical sector. The introduction of this tie rod is part of a broader portfolio that includes self drilling anchor bolts and hollow bar anchors, all designed to enhance safety and efficiency in construction.

In summary, the SupAnchor GFRP Tie Rod represents a significant advancement in formwork technology, driven by the brand's core values of professionalism, innovation, and collaboration. As construction industries evolve, such products are set to play a crucial role in shaping safer, more cost-effective infrastructures globally.

SupAnchor's innovative self drilling anchor bolts and geotechnical reinforcement systems are solving complex challenges in tunneling and slope stabilization projects across Europe.

Discover how SupAnchor's T thread self-drilling hollow anchor streamlines tunneling and slope stabilization projects through advanced engineering and corrosion-resistant designs.

Exploring how SupAnchor's innovative self-drilling anchor bolts provide solutions for challenging geotechnical projects, ensuring stability and efficiency in global infrastructure.

SupAnchor introduces the R thread self-drilling hollow anchor, featuring integrated drilling and grouting for faster, safer construction in challenging soil conditions.

SupAnchor's self drilling anchor bolt system provides robust foundation support in complex geotechnical conditions, highlighting innovation in ground stabilization for global infrastructure.