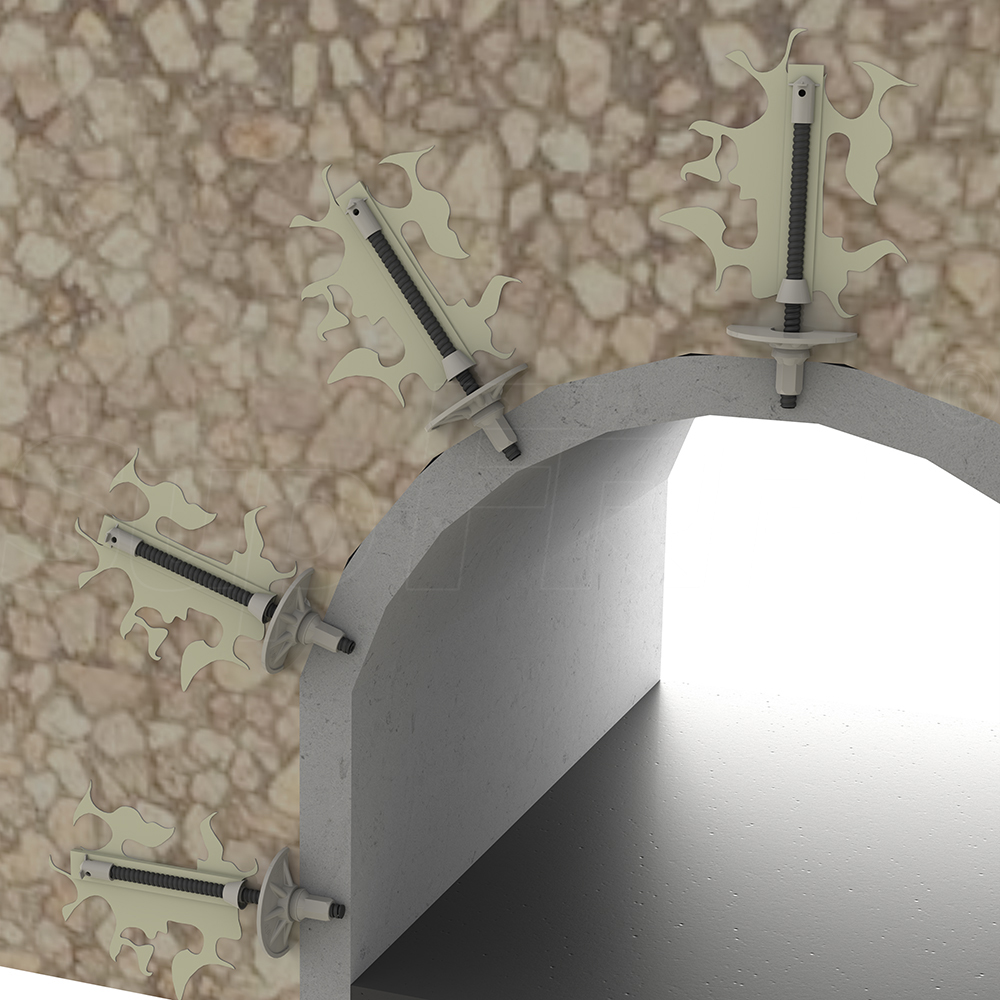

In the rugged terrains of European and American infrastructure projects, such as tunneling through unstable rock formations or stabilizing slopes in mountainous regions, engineers face persistent challenges like ground instability and corrosion. SupAnchor's GFRP Hollow Injection Bolt, a key product in the SupFRP series, plays a pivotal role by integrating drilling and grouting functions. After injection, the bolt remains in place, bearing loads with plates and nuts, and its excellent bond with grouting materials ensures full grouting under high pressure, significantly enhancing project durability and safety.

The self drilling anchor system from SupAnchor addresses critical engineering needs, such as high tensile demands and pressure resistance in confined spaces. For instance, in a typical tunneling scenario, the bolt's hollow design allows for efficient grout injection, filling voids and reinforcing weak zones. Key parameters include guaranteed tensile loads up to 490 kN, pressure resistance up to 30 MPa, and lightweight construction for easy handling. These features directly combat issues like rock fall and soil erosion, reducing installation time and costs. Below is a summary of technical data for the H25/220 model, highlighting its adaptability:

| Parameter | Value |

|---|---|

| Outside Diameter (mm) | 25 |

| Internal Diameter (mm) | 12 |

| Guaranteed Tensile Load (kN) | 220 |

| Pressure Resistance (MPa) | 5 |

| Weight (kg/m) | 0.64 |

This geotechnical reinforcement system ensures reliable performance in harsh conditions, with high corrosion resistance and cuttability allowing for precise adjustments on-site. By enabling full grouting, it minimizes the risk of voids, a common problem in drill-and-grout bolt applications, thus elevating overall project quality.

The hollow bar anchor finds extensive use in diverse settings, from slope stabilization in highway projects to TBM face support in urban tunneling. Its versatility shines in forepoling for tunnel advance and stabilization of soft rock in mining operations. For example, in a recent European slope project, the self drilling anchor bolt provided immediate support during excavation, preventing collapses and ensuring worker safety. Other applications include confined ground conditions and permanent installations, where its durability and ease of use reduce long-term maintenance. Key highlights include:

This adaptability makes it a cornerstone in modern geotechnical engineering, addressing global infrastructure demands efficiently.

SupAnchor's innovation in the self drilling anchor system aligns with global trends in sustainable infrastructure, supporting projects in tunneling, mining, and urban development. The company's R&D focus on high-performance materials, backed by ISO certifications, ensures that products like the GFRP bolt meet international standards. Collaborative efforts with engineering firms worldwide have led to successful deployments in challenging environments, reinforcing SupAnchor's reputation for professionalism and innovation. By enhancing geotechnical safety and reducing environmental impact, this drill-and-grout bolt contributes to safer, more resilient communities, embodying the brand's commitment to excellence and teamwork.

SupAnchor's innovative self drilling anchor bolts and geotechnical reinforcement systems are solving complex challenges in tunneling and slope stabilization projects across Europe.

Discover how SupAnchor's T thread self-drilling hollow anchor streamlines tunneling and slope stabilization projects through advanced engineering and corrosion-resistant designs.

Exploring how SupAnchor's innovative self-drilling anchor bolts provide solutions for challenging geotechnical projects, ensuring stability and efficiency in global infrastructure.

SupAnchor introduces the R thread self-drilling hollow anchor, featuring integrated drilling and grouting for faster, safer construction in challenging soil conditions.

SupAnchor's self drilling anchor bolt system provides robust foundation support in complex geotechnical conditions, highlighting innovation in ground stabilization for global infrastructure.