In a recent infrastructure project across challenging European terrains, engineers grappled with corrosion issues and heavy material weights in highway overlays. SupAnchor® stepped in with its innovative GFRP Mesh, offering a robust solution that aligns with modern geotechnical reinforcement systems. This mesh, developed through extensive research, addresses critical construction demands while promoting sustainability and safety.

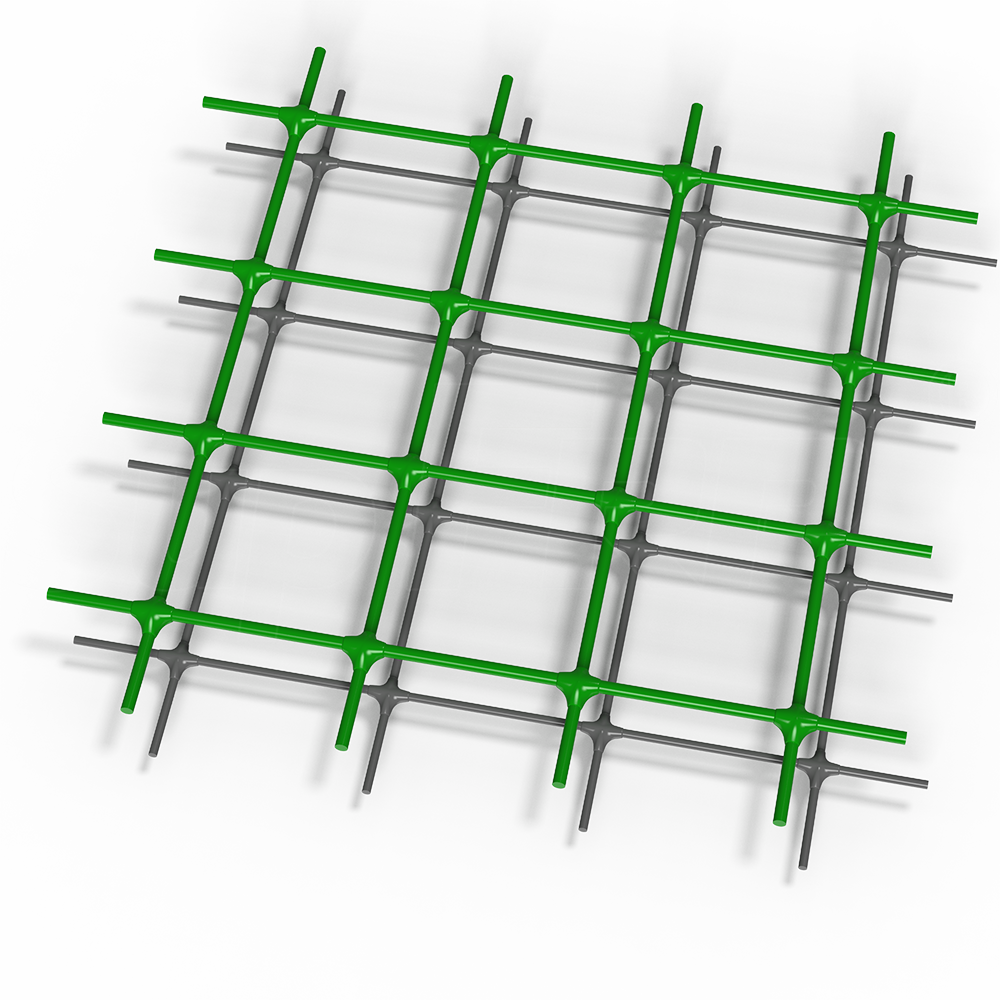

The SupAnchor® GFRP Mesh is engineered for versatility, with key technical data highlighting its adaptability. On-site, it simplifies installation in applications like flat slab construction, where its lightweight nature reduces labor costs and enhances workflow efficiency. The mesh's high strength and non-conductive properties make it an excellent alternative to traditional metal meshes, particularly in environments prone to electrical hazards or corrosion.

| Variant | Rod Diameter (mm) | Jointing Load (kN) | Grid Size (mm) |

|---|---|---|---|

| M4 | 4 | 2 | 100x100, 150x1500* |

| M6 | 6 | 3 | 100x100, 150x1500* |

| M8 | 8 | 5 | 100x100, 150x1500* |

* Other grid sizes available upon request. These specifications ensure reliable performance in diverse conditions, such as in repair of concrete structures, where the mesh's jointing load and diameter contribute to long-term stability. By integrating with self drilling anchor systems, it provides a cohesive geotechnical reinforcement solution that mitigates risks like structural failure.

The GFRP Mesh finds extensive use in various sectors, including roof and wall protection, where its corrosion resistance prolongs building lifespans. In highway overlays, it withstands heavy traffic loads and environmental stressors, while in tunneling and mining, it complements hollow bar anchor systems to enhance ground support. Its flexibility allows for easy adaptation to complex geometries, making it a preferred choice in projects requiring precise geotechnical reinforcement.

This adaptability is crucial in global infrastructure projects, where the mesh's properties align with the demands of drill-and-grout bolt applications, ensuring seamless integration into existing systems.

SupAnchor's GFRP Mesh contributes significantly to the geotechnical reinforcement industry by improving safety standards and reducing maintenance costs. In contexts like mining and urban development, it supports the evolution of self drilling anchor bolt technologies, fostering innovation. The company's commitment to R&D, backed by ISO certifications, has led to its involvement in international projects, from European tunnels to American highways, reinforcing its reputation for professionalism and collaboration.

By emphasizing a collaborative approach, SupAnchor ensures that its products, including the GFRP Mesh, meet the highest standards of quality and efficiency. This focus on innovation not only drives market value but also positions the brand as a leader in sustainable construction solutions, often working in tandem with soil nail system manufacturers to deliver comprehensive ground anchor bolt systems.

SupAnchor's innovative self drilling anchor bolts and geotechnical reinforcement systems are solving complex challenges in tunneling and slope stabilization projects across Europe.

Discover how SupAnchor's T thread self-drilling hollow anchor streamlines tunneling and slope stabilization projects through advanced engineering and corrosion-resistant designs.

Exploring how SupAnchor's innovative self-drilling anchor bolts provide solutions for challenging geotechnical projects, ensuring stability and efficiency in global infrastructure.

SupAnchor introduces the R thread self-drilling hollow anchor, featuring integrated drilling and grouting for faster, safer construction in challenging soil conditions.

SupAnchor's self drilling anchor bolt system provides robust foundation support in complex geotechnical conditions, highlighting innovation in ground stabilization for global infrastructure.