In the dynamic construction industry, projects often face challenges such as corrosive environments, high costs, and logistical inefficiencies, particularly in regions with demanding geological conditions. SupAnchor, a renowned manufacturer of geotechnical reinforcement systems, has stepped in with the SupFRP® GFRP Tie Rod, a groundbreaking product designed to address these issues. By providing a permanent formwork solution that eliminates the need for removal, this innovation not only cuts down on transportation and storage expenses but also enhances safety and durability. As part of SupAnchor's broader self drilling anchor system portfolio, this tie rod exemplifies the company's commitment to advancing construction methodologies, especially in large-scale infrastructure projects across Europe and America where efficiency and sustainability are paramount.

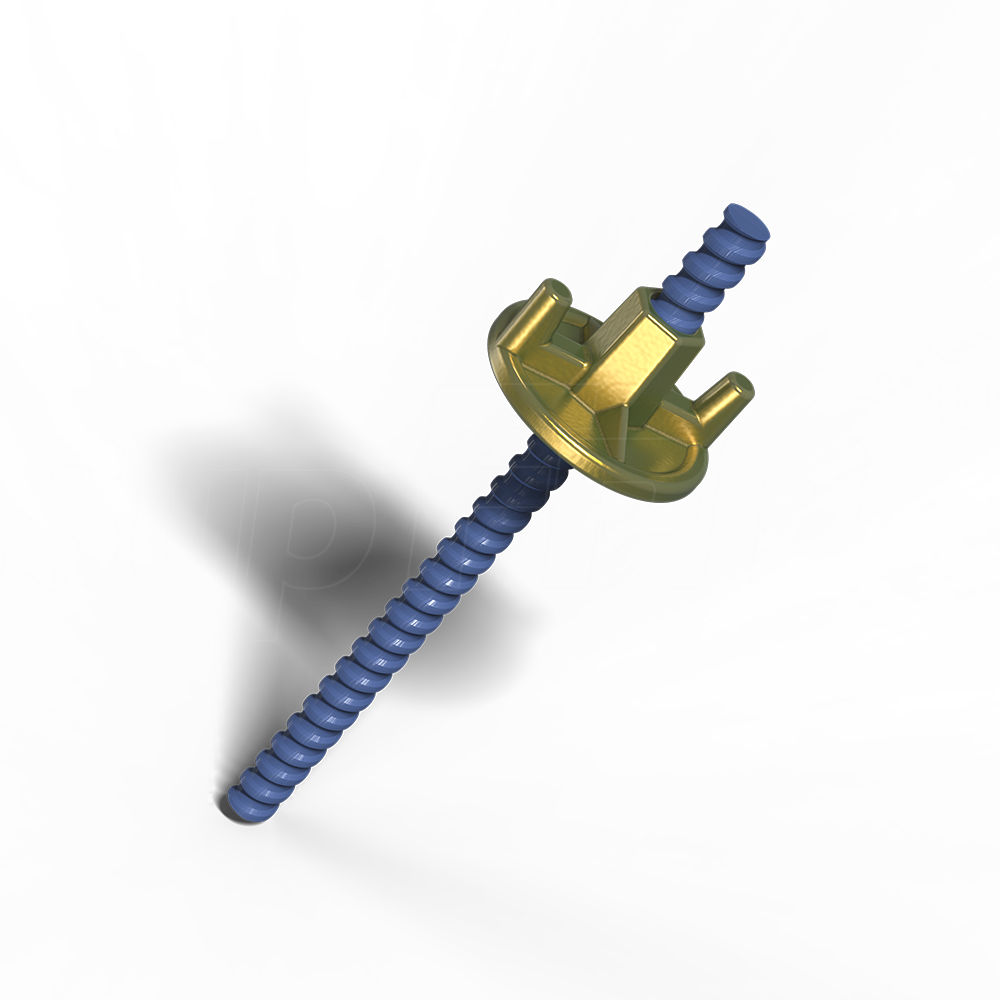

The SupFRP® GFRP Tie Rod is engineered to meet the rigorous demands of modern construction, featuring high corrosion resistance, strength, and compatibility with standard accessories. Key technical parameters, derived from extensive research, ensure it outperforms traditional steel rods in various scenarios. For instance, on a typical construction site, engineers can integrate this tie rod into formwork systems to handle high tensile loads without concerns over rust or removal, streamlining processes in projects like tunneling or mining where geotechnical reinforcement systems are critical. The product's design allows for easy handling and installation, reducing labor costs and time. Below is a detailed table of its technical data, showcasing how these specs tackle common engineering challenges such as weight management, load-bearing capacity, and environmental resilience.

| Parameter | T15/130 | T20/250 |

|---|---|---|

| Outside Diameter (mm) | 17 | 22 |

| Nominal Cross-sectional Area (mm²) | 130 | 250 |

| Guaranteed Tensile Load (kN) | 130 | 250 |

| Tensile E-Modulus (GPa) | 45 | 45 |

| Ultimate Strain (%) | 2.0 | 2.0 |

| Weight (kg/m) | 0.37 | 0.71 |

These specifications, such as the high tensile load of up to 250 kN and lightweight design, directly address issues like structural integrity and ease of transport. For example, in formwork applications, the tie rod's corrosion resistance ensures longevity in harsh conditions, while its non-conductive nature enhances safety near electrical systems. This makes it an ideal component in SupAnchor's self drilling anchor bolt systems, which are widely used for reliable ground anchoring in various terrains.

The SupFRP® GFRP Tie Rod is primarily designed for formwork in concrete structures, but its versatility extends to other geotechnical applications, including tunneling, mining, and infrastructure development. In real-world scenarios, such as a large-scale bridge construction in Europe, this product has demonstrated significant advantages by reducing the need for post-project rod removal, which traditionally incurs high costs and environmental impacts. Key benefits highlighted in field tests include:

These features not only improve efficiency but also support the integration with other SupAnchor products, such as hollow bar anchors and drill-and-grout bolts, creating a comprehensive geotechnical reinforcement system. For instance, in mining operations, the tie rod's high end loading capability helps secure formwork in unstable ground, preventing collapses and enhancing worker safety.

The introduction of the GFRP Tie Rod by SupAnchor holds substantial value for the global construction industry, particularly as nations invest in resilient infrastructure. In Europe and America, where regulations emphasize sustainability and cost-effectiveness, this product offers a viable alternative to traditional materials, potentially reducing project timelines and carbon footprints. By eliminating the removal phase, it addresses common pain points in large projects like subway tunnels or skyscrapers, where every saved hour translates to significant financial savings. Moreover, its role in enhancing geotechnical safety cannot be overstated; in applications involving soil nail systems or ground anchor bolts, the tie rod's durability ensures long-term stability, reducing the risk of failures in critical structures. This innovation aligns with global trends toward smarter, more efficient building methods, positioning SupAnchor as a key player in the evolution of construction technologies. As infrastructure demands grow, products like this will be crucial for meeting the challenges of urbanization and environmental stewardship, fostering a safer and more productive industry worldwide.

SupAnchor has built a strong reputation through decades of research and development, backed by ISO certifications and a track record of successful global projects. The company's focus on innovation is evident in products like the self drilling anchor system and now the GFRP Tie Rod, which stem from collaborative efforts with engineers and industry experts. By adhering to high standards of professionalism, SupAnchor ensures that their solutions are not only effective but also adaptable to diverse project needs. For example, in recent partnerships on European infrastructure initiatives, the tie rod has been praised for its ease of integration and performance under stress. This collaborative approach reinforces SupAnchor's brand message of being professional, innovative, and team-oriented, driving advancements that benefit the entire construction sector. As they continue to expand their influence, SupAnchor remains dedicated to pushing the boundaries of what's possible in geotechnical reinforcement, inspiring confidence among clients and stakeholders alike.

A report on how SupAnchor's self drilling anchor bolts solve geotechnical challenges in a major tunneling project, featuring technical specs and global industry relevance.

SupAnchor® GFRP SDA Bolt combines drilling, grouting, and anchoring for efficient geotechnical reinforcement, supporting infrastructure projects globally with high torque resistance and easy handling.

An industry report on SupAnchor's self drilling anchor bolts providing geotechnical reinforcement in a challenging Alpine slope project, highlighting technical specs and global trends.

SupAnchor introduces the SupCT Bolt System, a high-performance self-drilling anchor system with duplex corrosion protection and versatile applications in mining, tunneling, and infrastructure projects.

Industry report on SupAnchor's self drilling anchor system improving stability in challenging tunneling projects, highlighting technical specs and global trends.