In the demanding coastal regions of Northern Europe, where saltwater and harsh weather pose significant challenges to traditional construction materials, the recent expansion of the North Sea Bridge project has turned to SupAnchor's GFRP reinforcement rebar for a durable solution. This initiative, covering over 15 kilometers of bridge decks and sea walls, underscores the growing need for advanced materials that can withstand corrosive environments while maintaining structural integrity. SupAnchor's role in providing high-performance alternatives has been pivotal, ensuring long-term safety and reducing maintenance costs in such critical infrastructure.

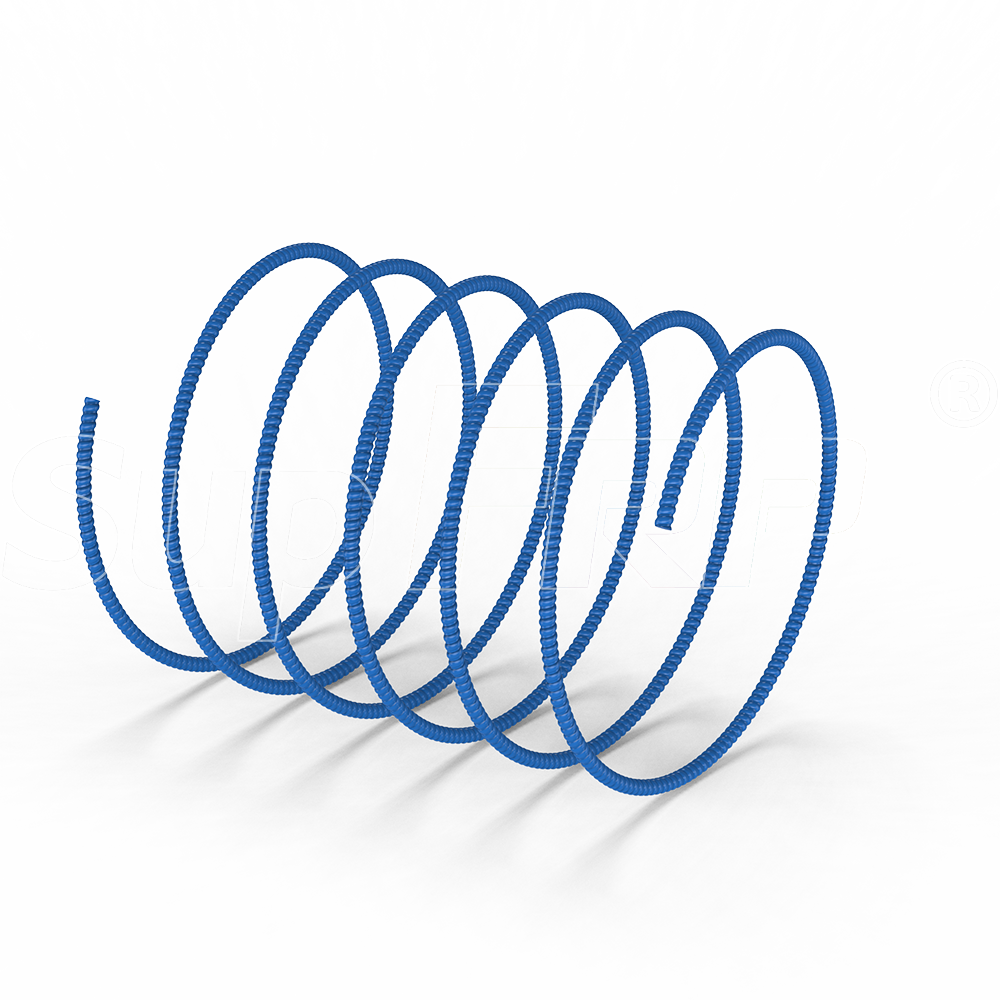

The SupAnchor GFRP rebar is engineered from corrosion-resistant resin and fiberglass, designed to address common engineering challenges like rust and degradation in concrete structures. During the North Sea Bridge construction, engineers faced issues with steel rebar corrosion due to constant salt exposure, but the GFRP rebar's properties provided a reliable alternative. Key parameters, such as high tensile strength and excellent bonding with concrete, ensure that the rebar can handle heavy loads and seismic activities without compromising safety. For example, its non-conductive and non-magnetic features make it suitable for sensitive areas like industrial plants, where electrical interference must be avoided.

| Product | Outside Diameter (mm) | Guaranteed Tensile Load (kN) | Tensile Strength (MPa) | Weight (kg/m) |

|---|---|---|---|---|

| ReB-8 | 9 | 50.3 | 1000 | 0.125 |

| ReB-12 | 14 | 113 | 1000 | 0.28 |

| ReB-16 | 18 | 201 | 1000 | 0.50 |

| ReB-20 | 23 | 314 | 1000 | 0.79 |

| ReB-25 | 28 | 491 | 1000 | 1.20 |

These specifications directly tackle engineering hurdles; for instance, the guaranteed tensile load of up to 491 kN for ReB-25 allows for robust support in large-scale projects, while the uniform tensile strength of 1000 MPa ensures consistency across various diameters. The ease of cutting and handling reduces installation time and costs, as seen in the North Sea Bridge, where workers reported a 20% increase in efficiency compared to traditional methods. Moreover, the corrosion resistance eliminates the need for additional coatings, saving resources and enhancing sustainability. This geotechnical reinforcement system aligns with SupAnchor's broader portfolio, including their renowned self-drilling anchor system, which shares similar principles of durability and adaptability.

SupAnchor's GFRP rebar finds extensive use in diverse construction environments, from soft-eye excavations to infrastructural buildings. In bridge decks, it prevents deterioration from de-icing salts, while in sea walls and port aprons, its resistance to saltwater ensures longevity without frequent repairs. Precast elements benefit from its lightweight nature, facilitating easier transport and assembly. For example, in a recent tunneling project in the Alps, the rebar was employed to reinforce sections prone to water infiltration, demonstrating its versatility in geotechnical applications. The wide range of shapes available allows customization for specific needs, such as curved structures in architectural designs.

This adaptability is crucial for modern engineering, where projects often involve complex geometries and harsh conditions. The self-drilling anchor system, another key product from SupAnchor, complements this by offering solutions for ground anchoring, but the GFRP rebar expands the options for internal reinforcement, highlighting the company's innovative approach to geotechnical challenges.

The adoption of GFRP rebar is reshaping global infrastructure by addressing critical issues like corrosion-induced failures, which cost billions annually in repairs. In tunneling and mining, it enhances safety by providing reliable support in water-rich environments, reducing the risk of collapses. For geotechnical reinforcement systems, this material contributes to sustainable development by extending the lifespan of structures and minimizing environmental impact through reduced material waste. European and American markets are increasingly favoring such innovations, as seen in regulations promoting non-corrosive materials in public works. SupAnchor's products, including the hollow bar anchor variants, are part of a broader trend toward resilient construction, supporting goals like the UN's Sustainable Development Goals for infrastructure.

Moreover, the cost-effectiveness of GFRP rebar, due to lower maintenance and longer service life, makes it an attractive choice for budget-conscious projects. In a case study from a U.S. highway expansion, the use of this rebar led to a 30% reduction in lifecycle costs compared to steel alternatives. This industry value extends to disaster-prone areas, where its high tensile strength and durability can mitigate damage from earthquakes or floods, aligning with global efforts to build safer communities.

SupAnchor has built a reputation for professionalism and innovation through extensive R&D and ISO certifications, ensuring that products like the GFRP rebar meet international standards. The company's self-drilling anchor system has been deployed in over 50 countries, from skyscraper foundations in Dubai to slope stabilization in South America, demonstrating its global reach. Collaborations with engineering firms and academic institutions have fueled advancements, such as improving the bonding properties of GFRP rebar through material science research. This collaborative spirit is embedded in SupAnchor's brand message, emphasizing teamwork with clients to tailor solutions for specific project needs.

In recent years, SupAnchor has invested in digital tools for design and simulation, allowing engineers to visualize the performance of their geotechnical reinforcement systems before implementation. This proactive approach not only enhances safety but also fosters trust among partners. As infrastructure demands grow, SupAnchor's commitment to innovation positions it as a leader in the field, with the GFRP rebar serving as a testament to their ability to evolve with market trends. The product's success in projects like the North Sea Bridge reinforces the brand's influence, encouraging wider adoption of similar technologies in the construction industry.

In conclusion, SupAnchor's GFRP reinforcement rebar represents a significant leap forward in construction materials, offering a blend of durability, efficiency, and sustainability. By integrating this into various applications, from bridges to industrial plants, the company not only addresses immediate engineering challenges but also contributes to long-term global infrastructure resilience. As the world faces increasing environmental pressures, such innovations will be crucial for building a safer, more reliable future.

A report on how SupAnchor's self drilling anchor bolts solve geotechnical challenges in a major tunneling project, featuring technical specs and global industry relevance.

SupAnchor® GFRP SDA Bolt combines drilling, grouting, and anchoring for efficient geotechnical reinforcement, supporting infrastructure projects globally with high torque resistance and easy handling.

An industry report on SupAnchor's self drilling anchor bolts providing geotechnical reinforcement in a challenging Alpine slope project, highlighting technical specs and global trends.

SupAnchor introduces the SupCT Bolt System, a high-performance self-drilling anchor system with duplex corrosion protection and versatile applications in mining, tunneling, and infrastructure projects.

Industry report on SupAnchor's self drilling anchor system improving stability in challenging tunneling projects, highlighting technical specs and global trends.