In the rugged terrain of the Swiss Alps, a high-speed rail tunnel project is pushing the boundaries of geotechnical engineering, with SupAnchor's self drilling anchor system playing a pivotal role in overcoming complex geological challenges. This ambitious infrastructure endeavor, spanning over 20 kilometers, faces unstable rock formations, high groundwater levels, and seismic activity, necessitating advanced reinforcement solutions. SupAnchor's expertise in foundation support, tunneling, and slope stabilization ensures that the project remains on track, minimizing risks and enhancing safety for workers and future commuters alike. The integration of their hollow bar anchor technology allows for efficient drill-and-grout processes, reducing installation time and environmental impact while maintaining structural integrity in one of Europe's most demanding construction sites.

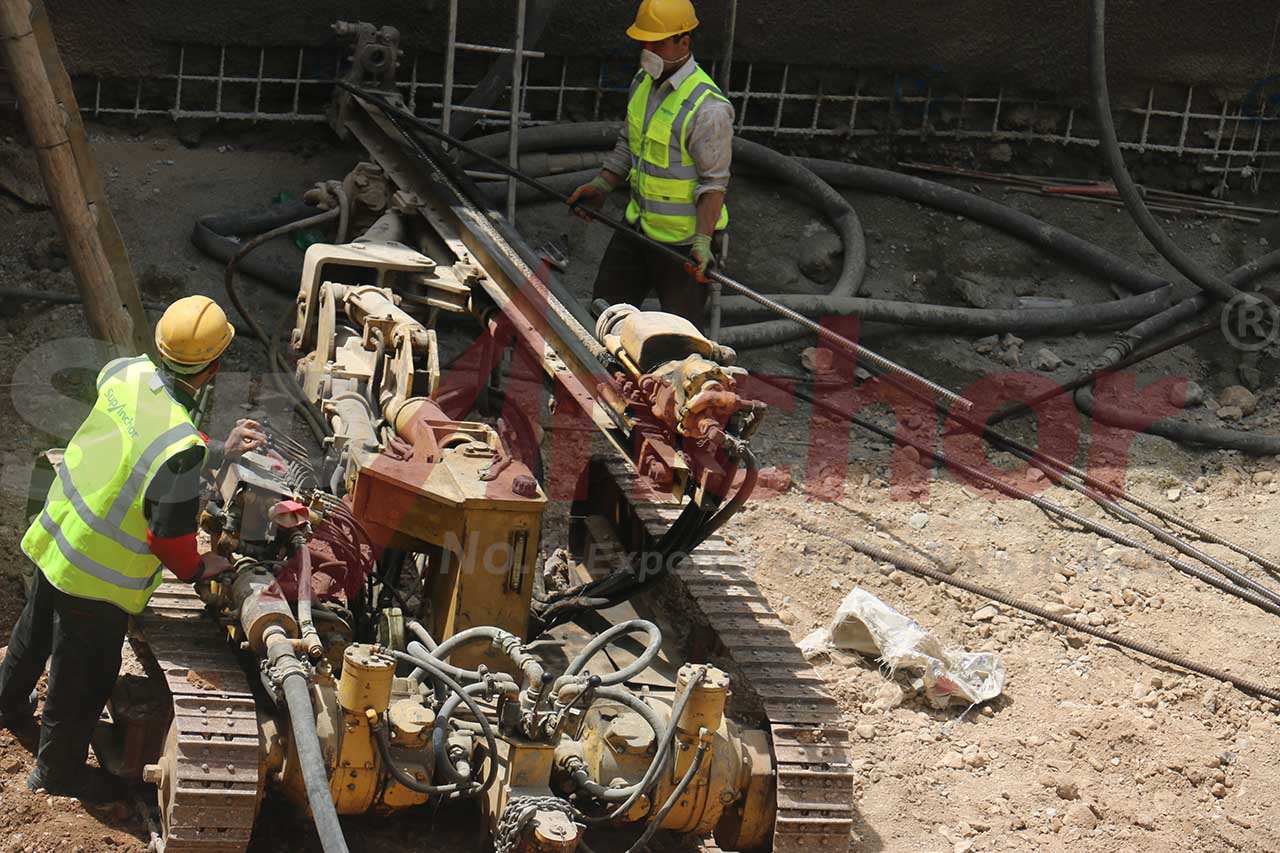

The construction site image vividly captures the deployment of SupAnchor's self drilling anchor bolts, where crews are securing tunnel walls against potential collapses. These geotechnical reinforcement systems are designed to address specific site challenges, such as loose soil and rock instability, by providing immediate support during excavation. Key product parameters include tensile strength, diameter, length, and corrosion protection, which are tailored to meet the project's rigorous demands. For instance, the high tensile strength ensures that the anchors can withstand significant loads from surrounding geology, while customizable lengths allow adaptation to varying depths. The following table outlines the essential specifications of SupAnchor's self drilling anchor bolt, illustrating how each parameter contributes to solving on-site issues like water infiltration and structural stress.

| Parameter | Value |

| Tensile Strength | 550 MPa |

| Diameter | 32 mm |

| Length | 6-12 m (customizable) |

| Corrosion Protection | Hot-dip Galvanized |

These specifications enable the self drilling anchor system to perform effectively in wet conditions, with the corrosion protection extending the lifespan of the anchors in humid Alpine environments. The drill-and-grout bolt methodology minimizes ground disturbance, a critical factor in preserving the natural landscape and reducing project delays. SupAnchor's ground anchor bolt factory emphasizes precision in manufacturing, ensuring that each component meets international standards for geotechnical engineering applications. By leveraging these technical advantages, the project team can achieve faster installation times and improved safety margins, underscoring the value of innovative solutions in modern civil engineering.

The adoption of SupAnchor's self drilling anchor system aligns with broader global trends in infrastructure development, where geotechnical safety and efficiency are paramount. As urbanization accelerates and climate change intensifies geological risks, projects like this Alpine tunnel highlight the growing demand for reliable ground stabilization anchor systems. In sectors such as transportation, mining, and urban development, technologies like rock bolts for underground mining and micropile hollow bar anchors are becoming standard for enhancing slope stability and supporting retaining walls. SupAnchor, as a soil nail system manufacturer, contributes to this evolution by providing SDA bolt factory direct supply, which streamlines procurement and reduces costs for large-scale projects. This approach not only supports sustainable development goals but also fosters collaboration among engineers, contractors, and suppliers to address complex geotechnical challenges worldwide.

SupAnchor's commitment to professionalism, innovation, and collaboration is evident in their role in this tunnel project and beyond. With ISO 9001 certification for quality management, the company ensures that their self drilling bolt for civil engineering meets the highest standards of reliability and performance. Their global portfolio includes diverse applications, from ground stabilization anchor systems in earthquake-prone regions to self drilling anchor for retaining walls in urban redevelopment projects. By focusing on research and development, SupAnchor continuously refines their anchor bolt system for geotechnical engineering, incorporating feedback from field applications to drive improvements. This collaborative ethos not only enhances project outcomes but also positions SupAnchor as a trusted partner in the industry, dedicated to advancing safety and efficiency through cutting-edge technologies.

In summary, SupAnchor's self drilling anchor system exemplifies how targeted innovation can transform geotechnical reinforcement, offering scalable solutions for infrastructure projects globally. As the industry moves towards more resilient and adaptive designs, the integration of such systems will be crucial for mitigating risks and ensuring long-term sustainability.

A report on how SupAnchor's self drilling anchor bolts solve geotechnical challenges in a major tunneling project, featuring technical specs and global industry relevance.

SupAnchor® GFRP SDA Bolt combines drilling, grouting, and anchoring for efficient geotechnical reinforcement, supporting infrastructure projects globally with high torque resistance and easy handling.

An industry report on SupAnchor's self drilling anchor bolts providing geotechnical reinforcement in a challenging Alpine slope project, highlighting technical specs and global trends.

SupAnchor introduces the SupCT Bolt System, a high-performance self-drilling anchor system with duplex corrosion protection and versatile applications in mining, tunneling, and infrastructure projects.

Industry report on SupAnchor's self drilling anchor system improving stability in challenging tunneling projects, highlighting technical specs and global trends.