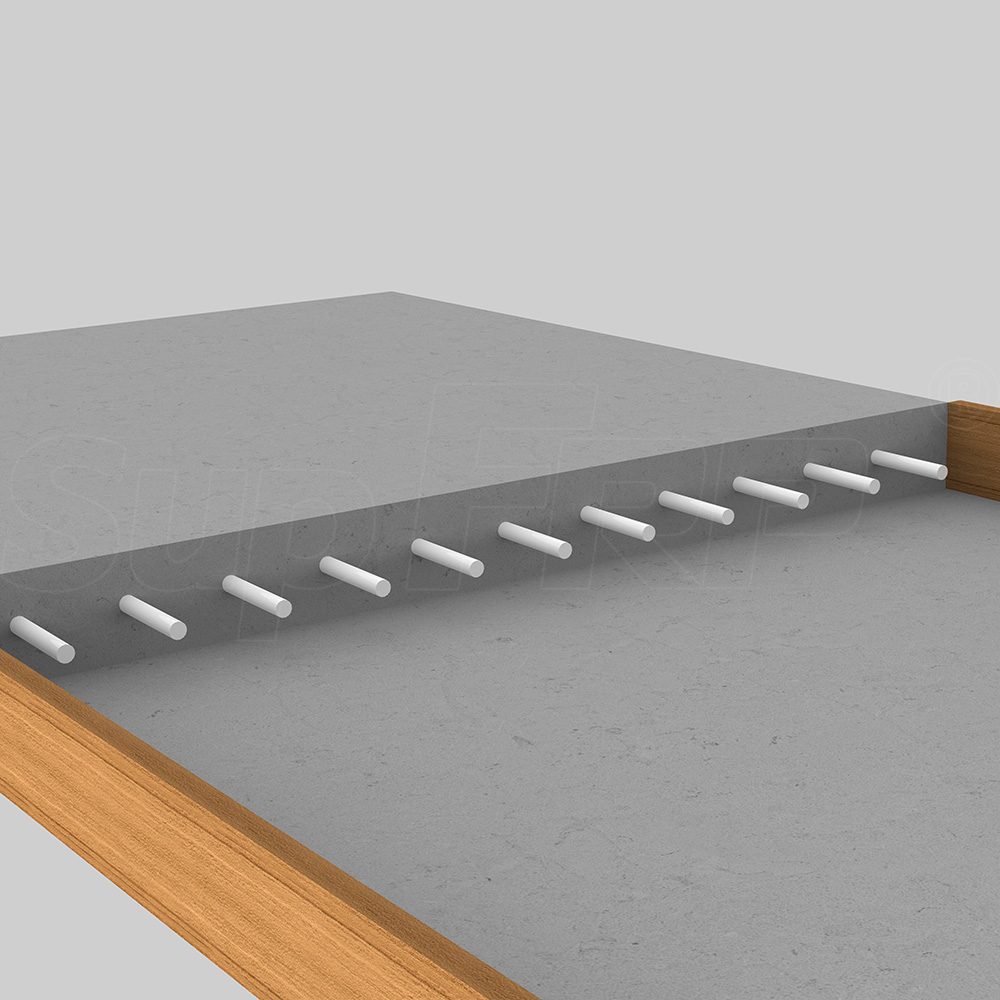

In Europe and North America, infrastructure development faces challenges like thermal expansion in concrete slabs, which can lead to cracking and reduced longevity. SupAnchor's GFRP Dowel Bar addresses these issues by serving as a reliable load transfer device, allowing horizontal movements to accommodate temperature changes. This innovation is part of SupAnchor's broader self drilling anchor system, designed for geotechnical reinforcement in various engineering contexts. As projects scale up in urban and rural settings, the need for durable, non-corrosive solutions becomes critical, positioning SupAnchor at the forefront of construction technology.

The SupFRP GFRP Dowel Bar is engineered with high-quality materials to meet rigorous demands. Key features include a service life exceeding 100 years, rust-free composition, high strength, superior load transfer efficiency, and non-conductive, non-magnetic properties. These attributes make it ideal for challenging environments. For example, in jointed rigid pavement, the dowel bar facilitates mechanical linking between slabs while permitting thermal movements, thus preventing structural failures. The following table outlines technical data for various models, highlighting how specifications like transverse shear load and weight contribute to solving engineering challenges such as load distribution and installation efficiency.

| Diameter (mm) | Transverse Shear Load (kN) | Nominal Cross-sectional Area (sq. m) | Weight (kg/m) |

|---|---|---|---|

| 16 | 35 | 200 | 0.43 |

| 20 | 55 | 310 | 0.67 |

| 25 | 85 | 490 | 1.05 |

| 32 | 130 | 800 | 1.71 |

| 38 | 180 | 1130 | 2.41 |

| 45 | 255 | 1590 | 3.37 |

Parameters such as the coefficient of thermal expansion (9-11 x10-6/°C) ensure compatibility with concrete behavior, reducing maintenance needs and enhancing safety. This geotechnical reinforcement system integrates seamlessly with other SupAnchor products, like the self drilling anchor bolt, to provide comprehensive solutions for soil nail systems and ground anchor applications.

The GFRP Dowel Bar finds use in diverse settings, including jointed rigid pavement, construction joints, embankments, mechanically stabilized earth (MSE) walls, and areas with electromagnetic sensitivities. For instance, in airports or medical facilities, its non-magnetic nature prevents interference with sensitive equipment. The product's customization options allow it to adapt to specific project requirements, such as in tunneling or mining where drill-and-grout bolts are commonly employed. By enabling efficient load transfer and movement accommodation, it supports long-term structural stability, making it a valuable component in SupAnchor's hollow bar anchor offerings for geotechnical projects.

Globally, infrastructure investments are shifting towards sustainability and resilience, with an emphasis on reducing lifecycle costs and enhancing safety. The GFRP Dowel Bar contributes by minimizing corrosion-related failures and extending service life, which is crucial in sectors like transportation, mining, and urban development. In Europe and America, regulations increasingly favor non-corrosive materials, aligning with SupAnchor's innovations. This product not only improves geotechnical safety but also supports economic growth by lowering maintenance expenses and enabling faster project completions. As part of a broader self drilling anchor system, it underscores the importance of advanced materials in modern engineering.

SupAnchor demonstrates professionalism and innovation through robust R&D initiatives and ISO certifications, ensuring high standards in manufacturing. The company's global projects, from highway constructions in Europe to bridge reinforcements in North America, highlight its collaborative approach with engineers and contractors. By developing tailored solutions like the GFRP Dowel Bar, SupAnchor reinforces its reputation as a leader in geotechnical reinforcement systems. The brand's commitment to quality and adaptability ensures that products meet evolving market demands, fostering partnerships that drive infrastructure advancement worldwide.

SupAnchor's GFRP Dowel Bar exemplifies the company's core values of professionalism, innovation, and collaboration, offering reliable performance in demanding environments. As infrastructure challenges grow, such innovations will play a pivotal role in shaping safer, more durable built environments.

A report on how SupAnchor's self drilling anchor bolts solve geotechnical challenges in a major tunneling project, featuring technical specs and global industry relevance.

SupAnchor® GFRP SDA Bolt combines drilling, grouting, and anchoring for efficient geotechnical reinforcement, supporting infrastructure projects globally with high torque resistance and easy handling.

An industry report on SupAnchor's self drilling anchor bolts providing geotechnical reinforcement in a challenging Alpine slope project, highlighting technical specs and global trends.

SupAnchor introduces the SupCT Bolt System, a high-performance self-drilling anchor system with duplex corrosion protection and versatile applications in mining, tunneling, and infrastructure projects.

Industry report on SupAnchor's self drilling anchor system improving stability in challenging tunneling projects, highlighting technical specs and global trends.