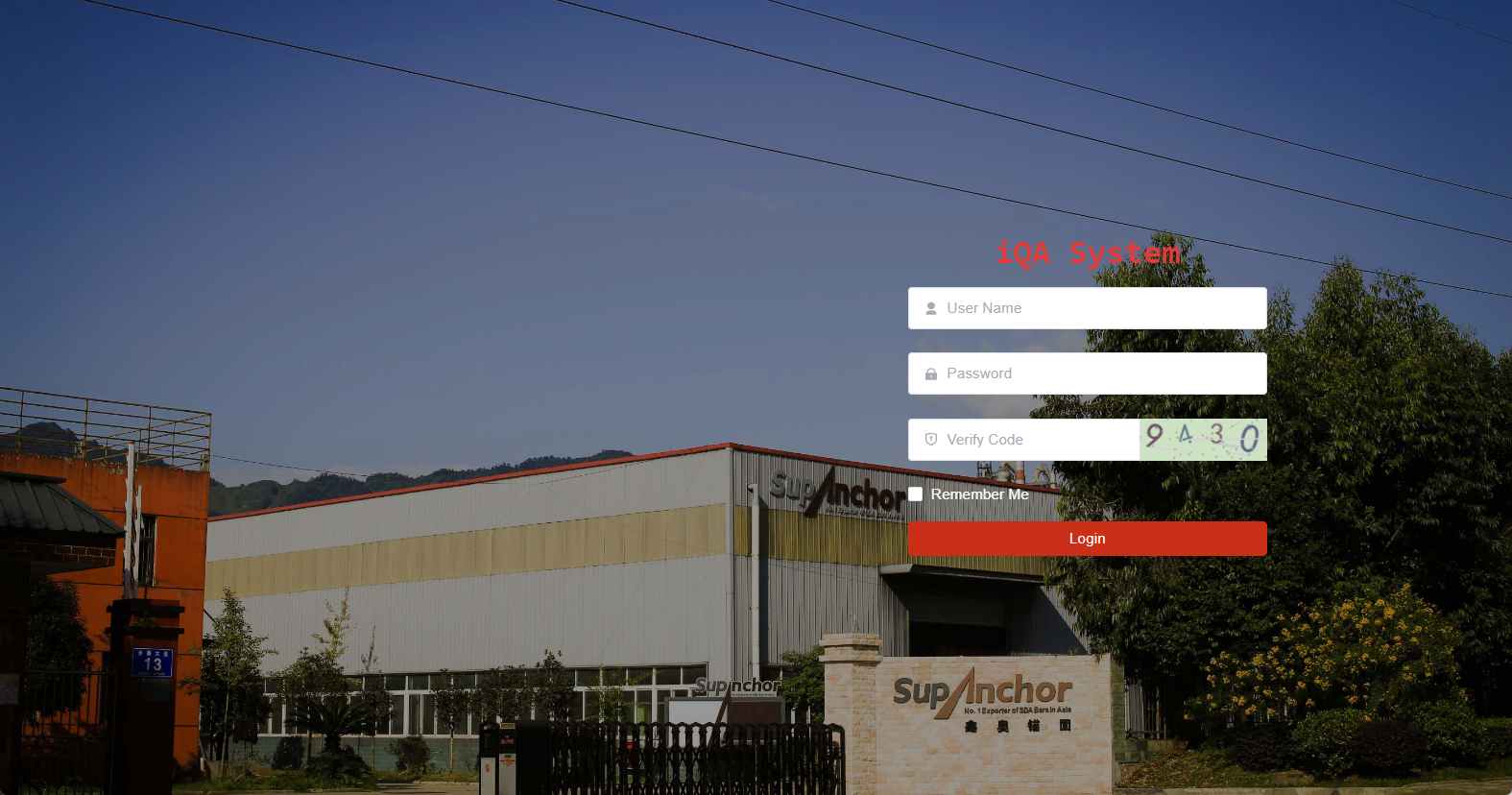

SupAnchor has recently introduced a brand-new Internal Management System (iQA), meticulously crafted by our skilled technical team and professionals, utilizing state-of-the-art techniques and precise data analysis to offer comprehensive support for quality control and supervision, meeting all customer needs and requirements.

The new system excels in quality control functionalities, providing real-time monitoring of every step in the production process and efficiently generating detailed quality reports. These reports showcase the reliability of our product quality, bolstering customer confidence and elevating our brand value.

We firmly believe that continuous innovation and technological advancement are the keys to maintaining an unbeatable position. Our digitization transformation is a crucial step as well, as we strive to integrate technology and production to enhance efficiency, reduce costs, and provide customers with even more competitive products. We are excitedly looking forward to creating a brighter future for our customers.

SupAnchor's innovative self drilling anchor bolt system provides reliable geotechnical reinforcement in a challenging construction site, addressing complex soil stabilization needs.

SupAnchor introduces a corrosion-resistant GFRP tie rod for permanent formwork applications, reducing costs and improving safety in global construction projects.

SupAnchor's advanced self drilling anchor bolt system ensures geotechnical reinforcement in challenging tunneling projects, highlighting innovation and safety in civil engineering.

SupAnchor's new SupHulk friction rock bolt system offers immediate load-bearing and adaptability, addressing challenges in mining and tunneling with advanced self-drilling anchor technology.

An in-depth look at how SupAnchor's innovative self drilling anchor bolts and geotechnical reinforcement systems are addressing complex challenges in global infrastructure, from tunneling to slope stabilization.