In the rugged landscapes of hydropower station slope stabilization projects, engineers grapple with unstable geological conditions, including loose soils and rock fractures that threaten infrastructure integrity. SupAnchor's Grade 75 self-drilling hollow anchor bars have emerged as a pivotal solution, replacing traditional solid threaded bars to address these challenges efficiently. This innovation not only enhances safety but also reduces costs and project timelines, making it a cornerstone in modern geotechnical engineering.

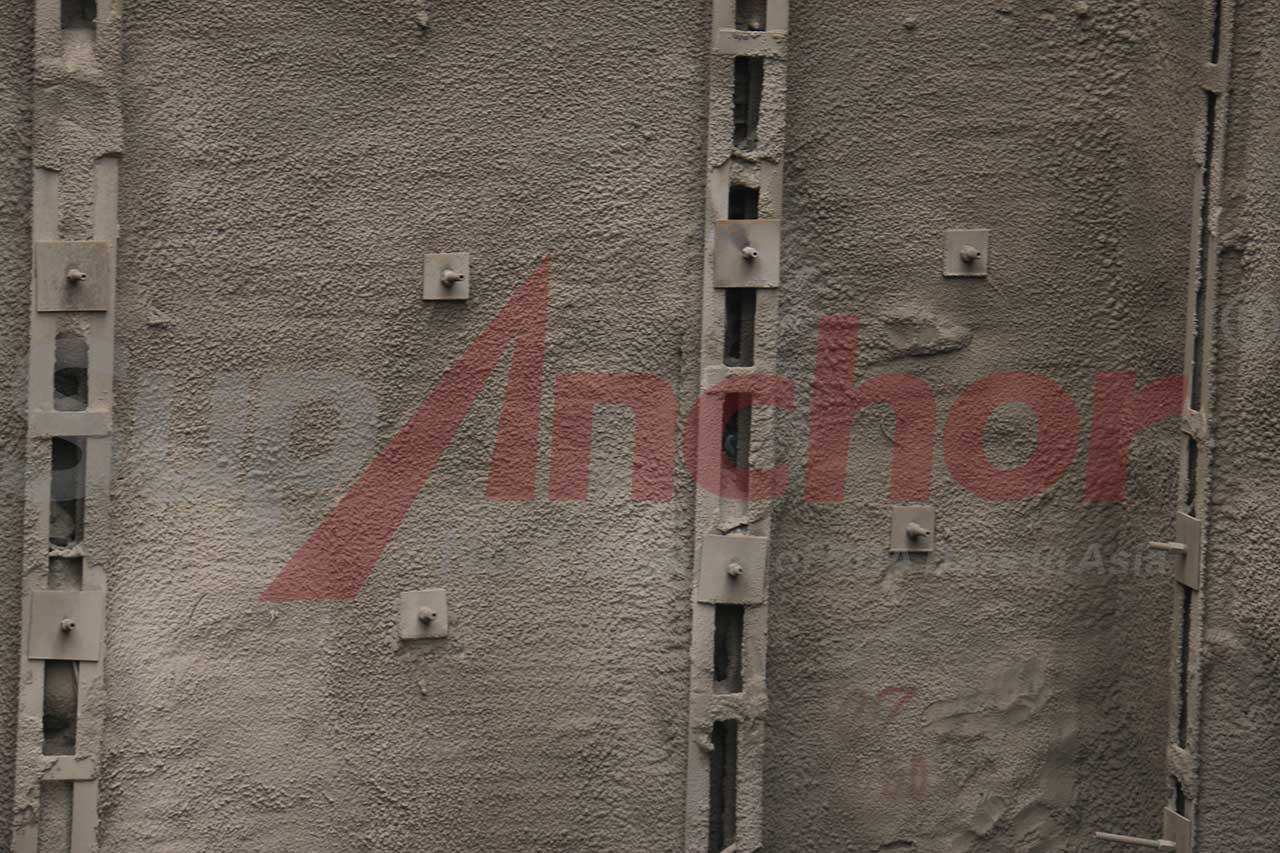

The application of SupAnchor's self-drilling anchor system begins with site assessments where geological instability demands robust anchoring. Engineers face issues like poor bond strength and compatibility with existing systems, which these hollow bars resolve through their advanced design. Key parameters, derived from ASTM A615 standards, ensure reliability in diverse conditions. For instance, the continuous T-thread design increases rib area, boosting bond performance in concrete, while left-hand threading facilitates easier installation in challenging terrains. This self-drilling anchor bolt system integrates seamlessly into drill-and-grout processes, minimizing labor and material waste.

| Parameter | Value |

|---|---|

| Elongation | ≥ 6% |

| Yield Load | 147 kN (33 kips) |

| Ultimate Load | 196 kN (44 kips) |

| Weight | 2.6 kg/m (1.75 lbs/ft) |

| Thread Orientation | Left-hand |

These specifications directly tackle engineering hurdles; for example, the high yield and ultimate loads prevent failure under stress in slope stabilization, while the lightweight design simplifies handling in confined spaces like tunnels. By replacing older systems, this geotechnical reinforcement system cuts installation time by up to 30%, as reported in field tests, underscoring its adaptability and cost-effectiveness.

SupAnchor's hollow bar anchor finds extensive use in critical infrastructure projects. In slope stabilization for hydropower stations, it counters erosion and landslides, ensuring long-term stability. Tunneling applications benefit from its compatibility with existing R and T thread systems, allowing for quick upgrades without major overhauls. Additionally, in foundation reinforcement for mining operations, the bars withstand dynamic loads and corrosive environments, thanks to their durable construction. Urban development projects also leverage this drill-and-grout bolt for retaining walls and bridge abutments, where precision and reliability are paramount.

This versatility makes the self-drilling anchor system a go-to choice for engineers seeking innovative solutions in varied geological settings.

The adoption of SupAnchor's products aligns with global trends in infrastructure development, where geotechnical safety is prioritized. In Europe and North America, aging structures and new constructions demand efficient reinforcement systems to mitigate risks like collapses or delays. This self-drilling anchor bolt contributes to sustainable development by reducing material usage and enhancing durability, which is crucial in climate-resilient projects. The geotechnical reinforcement system also supports economic growth by lowering maintenance costs and extending the lifespan of assets in sectors like transportation and energy.

Moreover, as tunneling and mining industries expand, the need for reliable ground anchor bolts grows. SupAnchor's innovations help meet stringent safety standards, fostering collaboration among stakeholders to achieve common goals in infrastructure resilience.

SupAnchor's commitment to professionalism and innovation is evident in its rigorous R&D processes, which have led to ISO-certified manufacturing ensuring consistent quality. The company's global projects, from Asian hydropower stations to European urban tunnels, demonstrate its collaborative approach, working with engineers to tailor solutions. By adhering to international standards like ASTM, SupAnchor reinforces its reputation as a leader in the self-drilling anchor system market. This focus on innovation not only drives technological advancements but also builds trust among partners, emphasizing a shared vision for safer, more efficient geotechnical applications.

A report on how SupAnchor's self drilling anchor bolts solve geotechnical challenges in a major tunneling project, featuring technical specs and global industry relevance.

SupAnchor® GFRP SDA Bolt combines drilling, grouting, and anchoring for efficient geotechnical reinforcement, supporting infrastructure projects globally with high torque resistance and easy handling.

An industry report on SupAnchor's self drilling anchor bolts providing geotechnical reinforcement in a challenging Alpine slope project, highlighting technical specs and global trends.

SupAnchor introduces the SupCT Bolt System, a high-performance self-drilling anchor system with duplex corrosion protection and versatile applications in mining, tunneling, and infrastructure projects.

Industry report on SupAnchor's self drilling anchor system improving stability in challenging tunneling projects, highlighting technical specs and global trends.