In a recent high-profile tunneling project through the unstable rock formations of the European Alps, engineers faced significant challenges with ground instability and safety concerns. SupAnchor's self drilling anchor system was deployed to provide essential foundation support, enabling efficient slope stabilization and ensuring the project's success. This geotechnical reinforcement system has proven invaluable in such demanding environments, where traditional methods fall short.

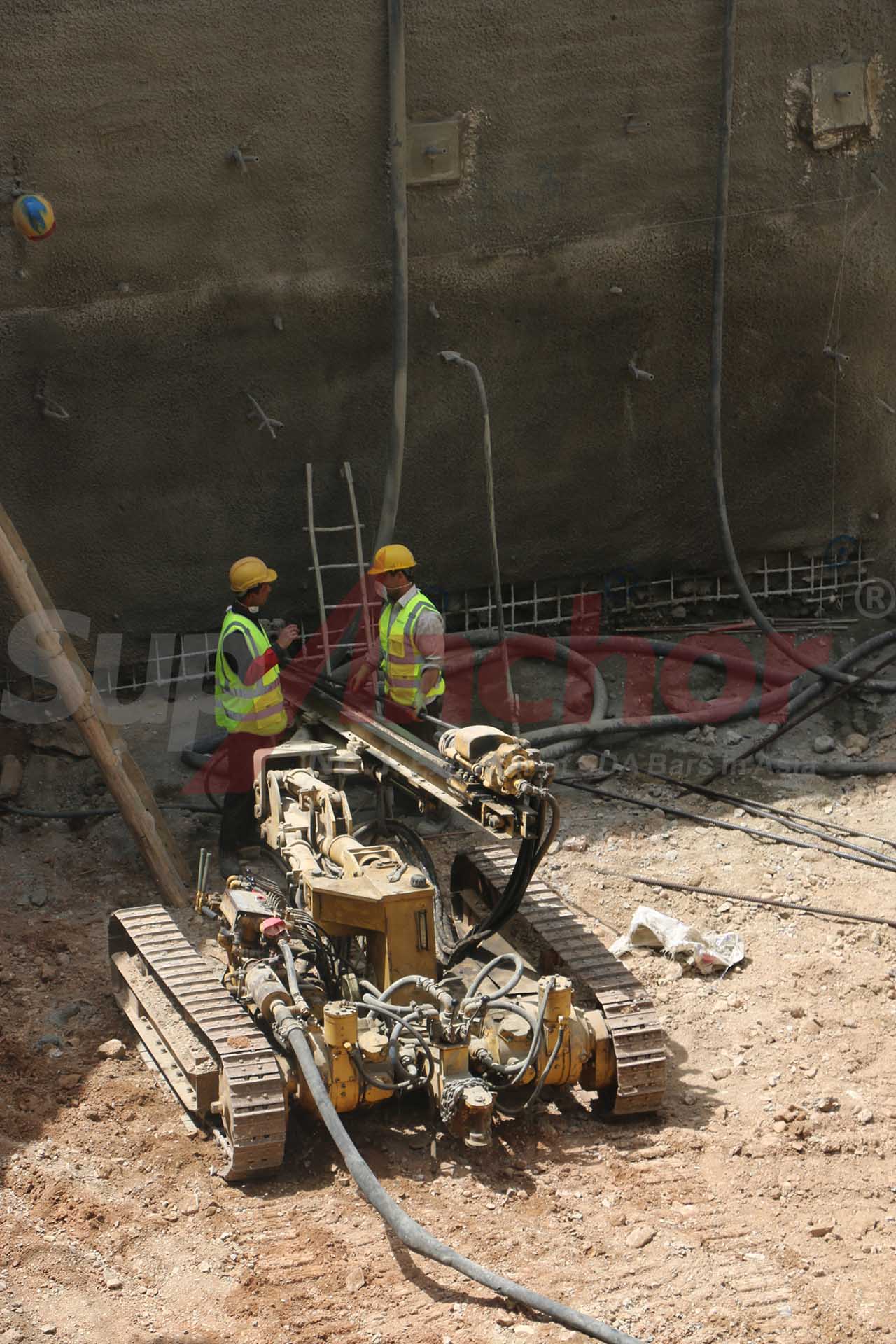

The construction scene, as captured in the image, illustrates the precise installation of SupAnchor's self drilling anchor bolts in rugged terrain. These hollow bar anchors are designed for drill-and-grout applications, offering superior performance. Key parameters include:

| Parameter | Value |

|---|---|

| Tensile Strength | 600 kN |

| Diameter | 32 mm |

| Length | 8 m |

| Corrosion Protection | Hot-dip galvanized |

| Yield Strength | 550 MPa |

These specifications allow the self drilling anchor bolt to handle high loads and resist corrosion, making it ideal for civil engineering projects. The system's efficiency reduces installation time and costs, addressing site-specific challenges like rock bolting for underground mining and retaining wall applications.

The use of self drilling anchor systems is growing globally, driven by increased infrastructure investments in transportation and urban development. SupAnchor's products align with trends in geotechnical safety, particularly in tunneling and slope stabilization projects. This ground stabilization anchor system supports sustainable construction practices and enhances overall project reliability.

SupAnchor, as a leading soil nail system manufacturer, emphasizes innovation, quality, and collaboration. With ISO 9001 certification, their ground anchor bolt factory ensures high standards, and their global projects demonstrate a commitment to professional solutions. The company's self drilling bolt for civil engineering is a testament to their innovative approach, providing factory direct supply for cost-effective geotechnical engineering applications.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.