In the dynamic world of construction, projects frequently encounter obstacles such as corrosion, high operational costs, and environmental sustainability concerns. SupAnchor®, a prominent player in geotechnical reinforcement systems, has launched the SupFRP® GFRP Tie Rod, a groundbreaking product designed to address these challenges in formwork applications. This innovation is particularly relevant for large-scale infrastructure projects, where durability and efficiency are paramount.

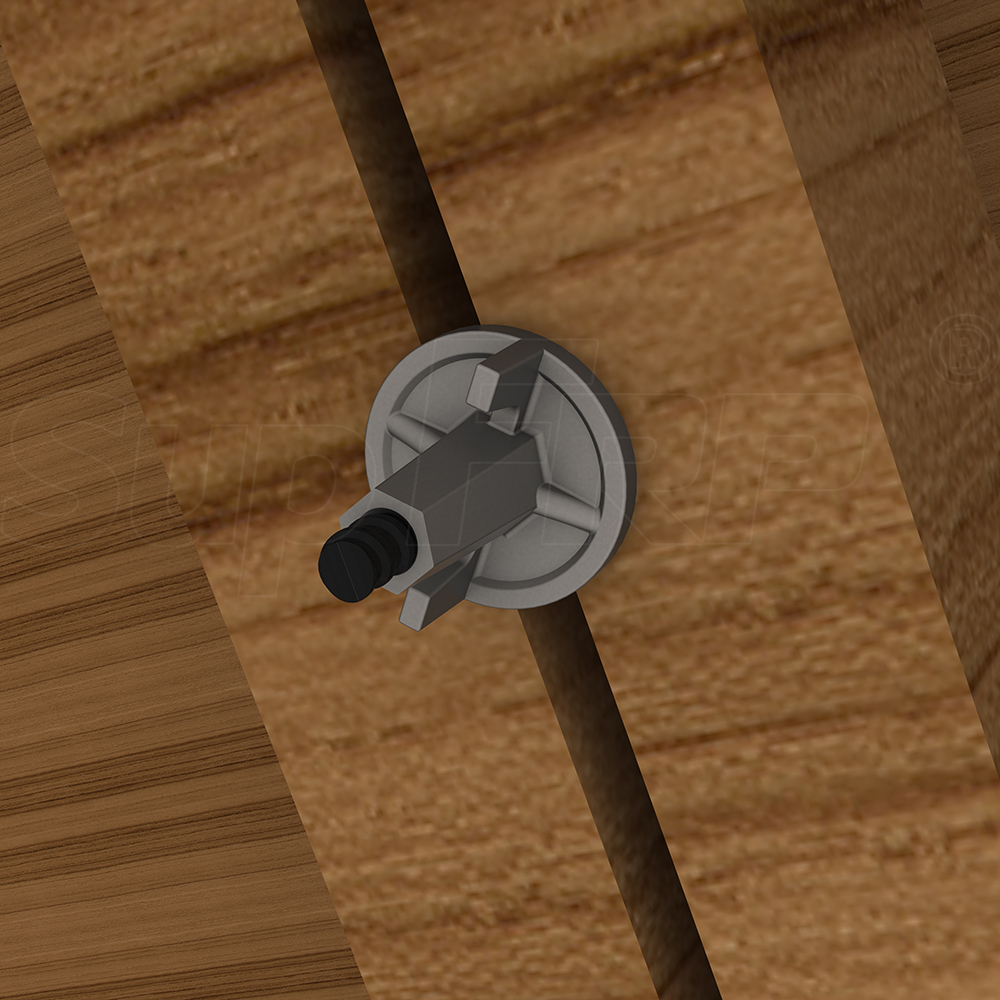

The SupFRP® GFRP Tie Rod is crafted from high-quality glass fiber reinforced polymer, offering superior performance compared to traditional steel alternatives. It is engineered to match the thread profile of standard steel rods, ensuring compatibility with existing accessories and simplifying integration into various projects. Key technical specifications for the available models are detailed in the table below, highlighting parameters such as diameter, tensile load, and modulus of elasticity.

| Model | Outside Diameter (mm) | Nominal Cross Sectional Area (mm²) | Guaranteed Tensile Load (kN) | Tensile E-Modulus (GPa) | Ultimate Strain (%) | Weight (kg/m) | Length (m) |

|---|---|---|---|---|---|---|---|

| T15/130 | 17 | 130 | 130 | 45 | 2.0 | 0.37 | 2 to 11 |

| T20/250 | 22 | 250 | 250 | 45 | 2.0 | 0.71 | 2 to 11 |

These specifications enable the tie rod to handle significant loads while providing high corrosion resistance, making it suitable for harsh environments like coastal areas or industrial sites. The product's non-conductive and non-magnetic properties enhance safety in electrical or sensitive applications. Unlike steel tie rods, it remains permanently in place after project completion, drastically reducing costs associated with transportation, storage, and removal. This feature is especially beneficial in complex projects such as tunneling or mining, where efficiency and reliability are critical.

The GFRP tie rod finds extensive use in various construction scenarios, including formwork for bridges, buildings, and underground structures. For instance, in a hypothetical tunnel project beneath the Alps, engineers faced issues with steel corrosion and high maintenance costs. By adopting SupAnchor's self drilling anchor system and the new GFRP tie rod, they achieved improved geotechnical safety and long-term savings. The product's ease of handling and cuttability allows for customization on-site, adapting to specific engineering needs without compromising strength or integrity.

Advantages of the SupFRP® GFRP Tie Rod include:

This innovation aligns with global trends towards sustainable construction, as it reduces material waste and environmental impact. SupAnchor's hollow bar anchor and drill-and-grout bolt systems have already set industry standards, and the GFRP tie rod complements these by offering a versatile solution for modern engineering challenges.

SupAnchor has established itself as a leader in the field through continuous research and development, backed by ISO certifications and a portfolio of successful global projects. Their focus on innovation is evident in products like the self drilling anchor bolt, which has been deployed in numerous infrastructure developments worldwide. The company emphasizes a collaborative approach, working closely with engineers and contractors to tailor solutions that meet specific project requirements. This professional ethos ensures that SupAnchor's offerings, including the GFRP tie rod, deliver reliable performance and enhance overall project outcomes.

In summary, the SupFRP® GFRP Tie Rod represents a significant advancement in construction technology, providing a durable, cost-effective alternative to traditional materials. SupAnchor's dedication to professionalism, innovation, and collaboration continues to drive progress in the geotechnical reinforcement system industry, benefiting projects across Europe, America, and beyond. For more insights, a demonstration video is available, showcasing the product's application in real-world scenarios.

Industry report on SupAnchor's self drilling anchor system stabilizing slopes in a complex tunneling project, highlighting technical specs and global geotechnical trends.

SupAnchor introduces a stainless steel self-drilling hollow anchor, designed to combat corrosion in coastal, marine, and industrial projects, ensuring long-term durability and safety.

An in-depth look at SupAnchor's self-drilling anchor bolts applied in a challenging Alpine construction, highlighting technical specs and industry relevance for global infrastructure.

SupAnchor's new GFRP Mesh offers high corrosion resistance, strength, and lightweight design, ideal for applications like highway overlays and concrete repair in global infrastructure projects.

Exploring how SupAnchor's self drilling anchor system addresses complex geotechnical challenges in modern construction, driving safety and innovation in infrastructure projects.