Advantages: The SupCT-Bolt®

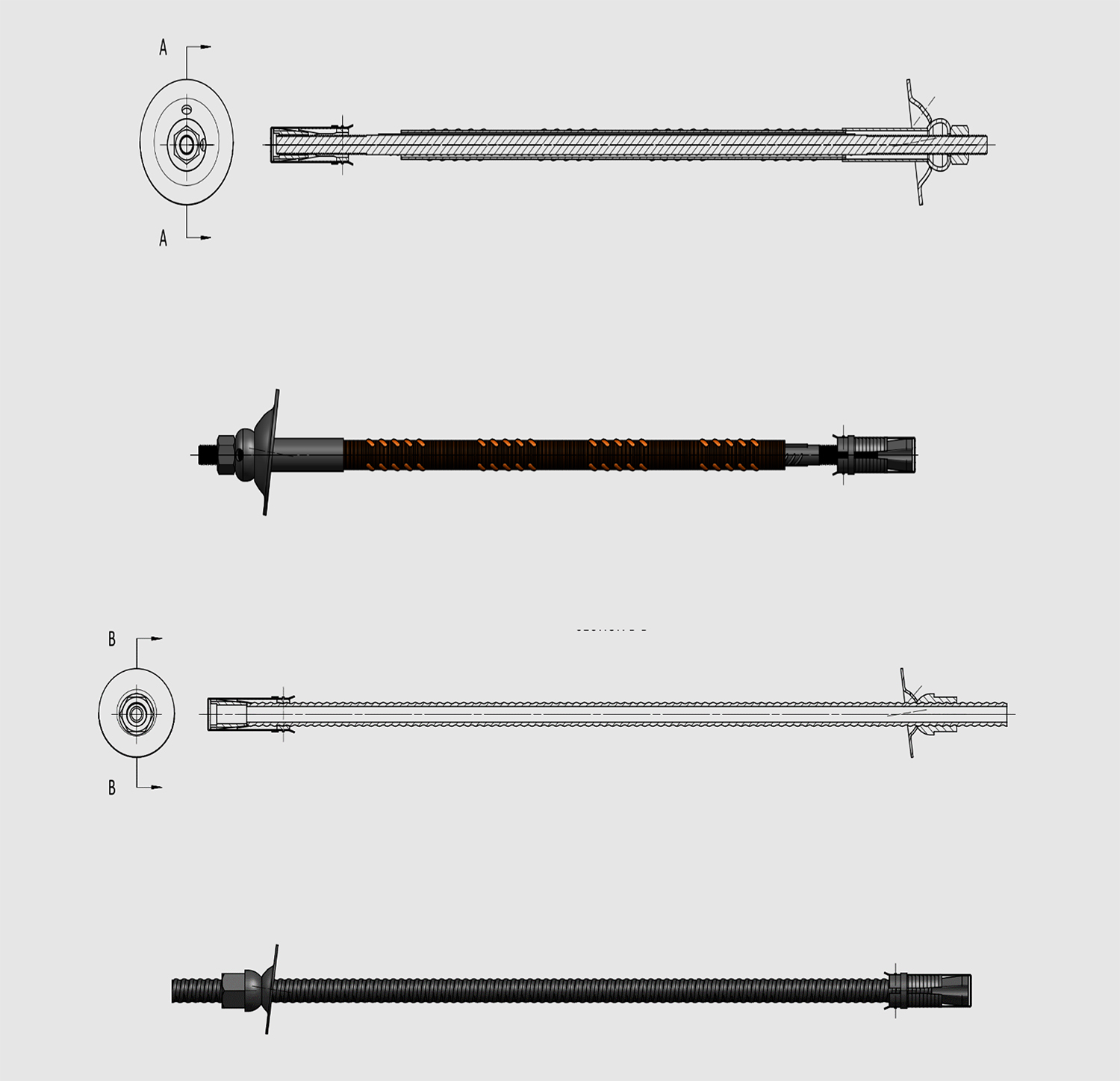

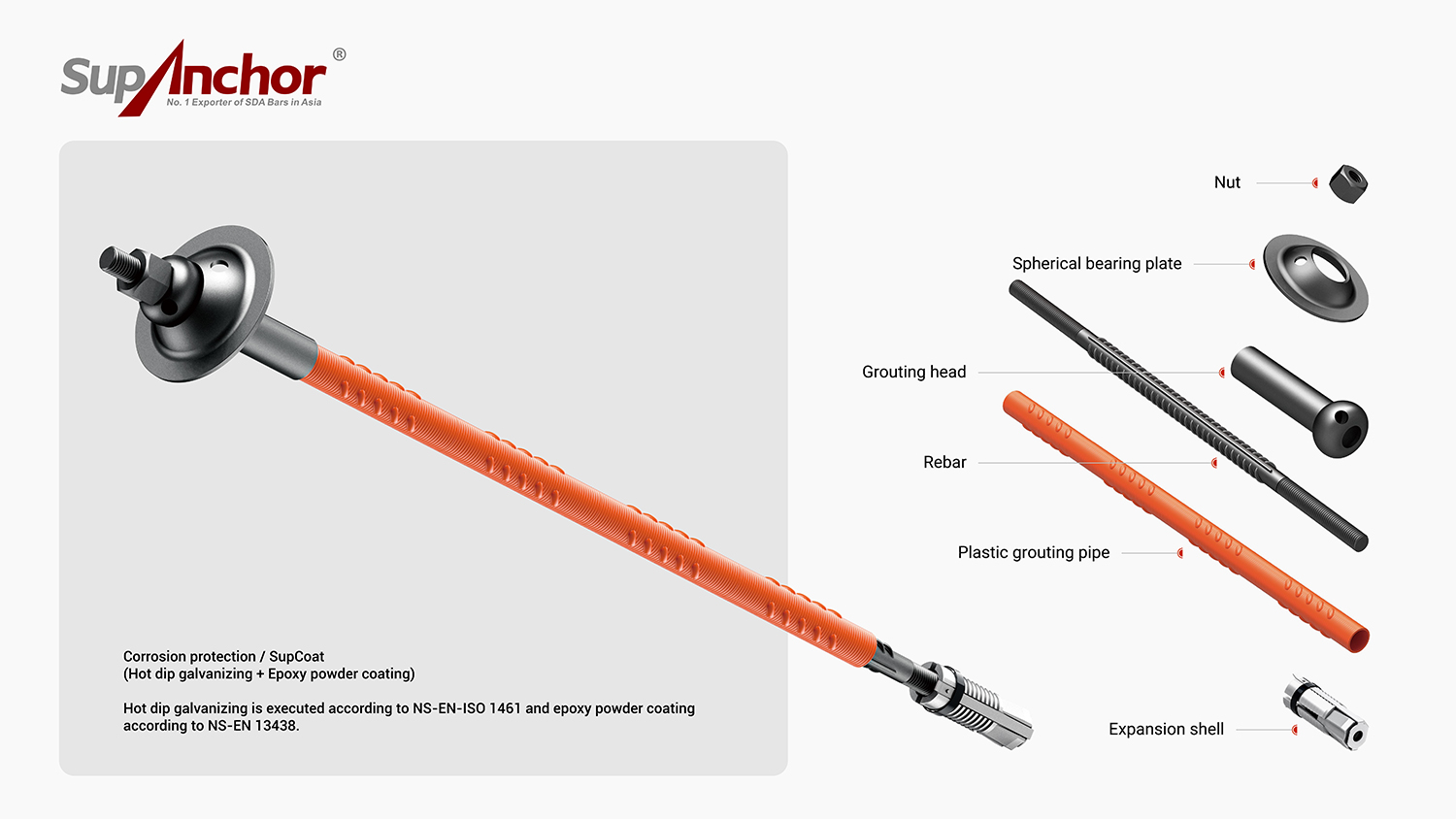

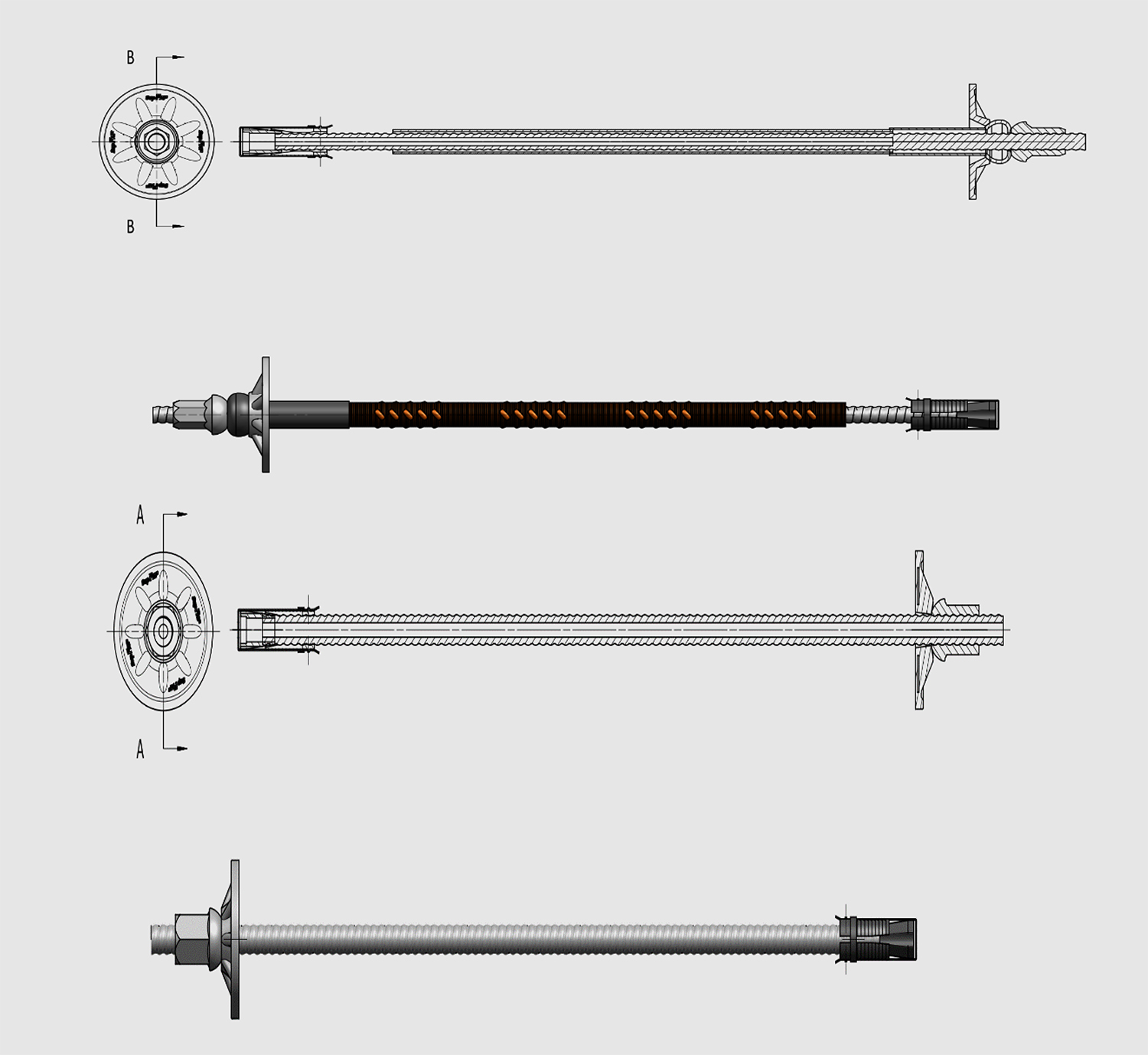

• Duplex corrosion protection: Hot dip galvanized and epoxy powder coated rebar bolt placed within a plastic grouting pipe and completely embedded in mortar, provides extended durability under all conditions.

• Highly efficient because it is suitable in most ground conditions and covers both immediate and permanent support in a single bolt.

• Durability testing of SupCT-Bolts shows that to improve on the Duplex system, stainless steel would be required for bolts and accessories.

• Bolts are delivered with zinc coated expansion shells mounted from factory. This ensures proper function of the threads and the coating prevents corrosion. Less work on site saves time and there are fewer parts to handle for stock management.

• Bolts are clamped in groups and loaded on pallets. This prevents transport damage and simplifies managing number of bolts in stock.

• Short distance from end of grouting pipe to expansion shell, ensures filling of borehole end, before mortar fills the rest of the hole.

• The bolt head design prevents leakage and risk of mortar spray against operators.

• Rebar anchorage tests show that the plastic grouting pipe bubble design provides excellent pull-out resistance for the rebar steel.

| Characteristic Value | Unit | Steel Bolt | |||||

| Steel solid bolt | Steel hollow bolt | ||||||

| Type | SSB-M20 | SSB-M22 | SSB-M33 | SHB-R2715 | SHB-R2712 | ||

| Weight | Kg/m | 2.47 | 2.98 | 6.43 | 2.47 | 2.98 | |

| Thread designation | mm | M20 | M22 | M33 | R27 | R27 | |

| Fully grouted | Yield load | kN | 157 | 239 | 402 | 159 | 246 |

| Ultimate load | kN | 186 | 300 | 482 | 191 | 270 | |

| End anchored | Yield load | kN | 123 | 191 | 347 | 159 | 246 |

| Ultimate load | kN | 147 | 239 | 416 | 191 | 270 | |

| Borehole | Diameter | mm | 45 - 48 | 45 - 48 | 64 - 68 | 45 - 48 | 45 - 48 |

| Depth | mm | Bolt length + 150 mm | Bolt length + 150 mm | ||||

| Materia | HRB500E 1) | 40Cr 2) | |||||

| Elongation | Agt ≥ 8% | Agt ≥ 5% 3) | |||||

| Service life | 50 years (black type) to 150 years ( SupCoat 4)) | ||||||

| Torque | Nm | 150 - 250 | 150 - 250 | 200 - 300 | 200 - 400 | 200 - 400 | |

| Pre-tension | kN | 40 - 60 | 20 - 40 | ||||

| Delivery lengths | m | 1.5 – 6.0 | 1.5 – 6.0 | ||||

1) According to GB1499.2-2007

2) According to DIN EN 10083,DIN EN ISO 683, ASTM A29/A29M-04

3) According to DIN 488

4) SupCoat = Hot Dip Galvanization (HDG) + Powder coating (Epoxy)

5) Poor and soft rock quality may give lower values. Test on site under actual conditions to correctly establish representative values.

| Characteristic Value | Unit | GFRP Bolt | ||||||

| GFRP solid bolt | GFRP hollow bolt | |||||||

| Type | GSB-R22 | GSB-R25 | GSB-R32 | GHB-R25 | GHB-R28 | GHB-R32 | ||

| Weight | Kg/m | 0.69 | 0.9 | 1.45 | 0.63 | 0.88 | 0.99 | |

| Rebar OD | mm | 22 | 25 | 32 | 12/25 | 28/12 | 32/15 | |

| Thread designation | mm | R22 | R25 | R32 | R25 | R28 | R32 | |

| Fully grouted | Yield load | kN | - | - | - | - | - | - |

| Ultimate load | kN | 250 | 350 | 560 | 220 | 280 | 360 | |

| End anchored load | GFRP nut | kN | 60 | 70 | 90 | 70 | 80 | 90 |

| L70 mm | ||||||||

| Steel nut L100 mm | kN | 140 1) | 180 | 230 | 180 | 200 | 230 | |

| Borehole | Diameter | mm | 45 - 48 | 45 - 48 | 64 - 68 | 45 - 48 | 45 - 48 | 64 - 68 |

| Depth | mm | Bolt length + 150 mm | Bolt length + 150 mm | |||||

| Materia | GFRP | GFRP | ||||||

| Elongation | 0.02 | 0.02 | ||||||

| Service life | Permanent | Permanent | ||||||

| Torque | Nm | 120 - 150 | 140 - 170 | 200 - 250 | 200-250 | 280-350 | 380-450 | |

| Pre-tension | kN | 40 - 60 | 40 - 60 | |||||

| Delivery lengths | m | 1.5 – 6.0 | 1.5 – 6.0 | |||||

1) Steel nut length L70mm

Poor and soft rock quality may give lower values. Test on site under actual conditions to correctly establish representative values.

The properties and test methods of GFRP bolt refer to CSA S807 and ACI 440.6M, as well as ASTM D7957M